AUTOSPOOL

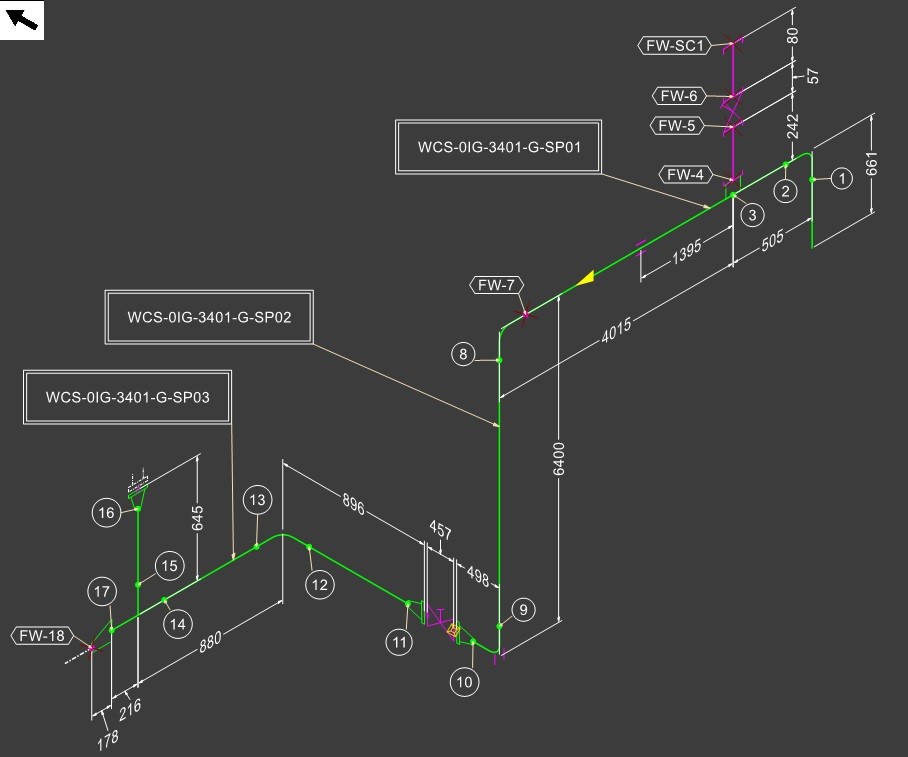

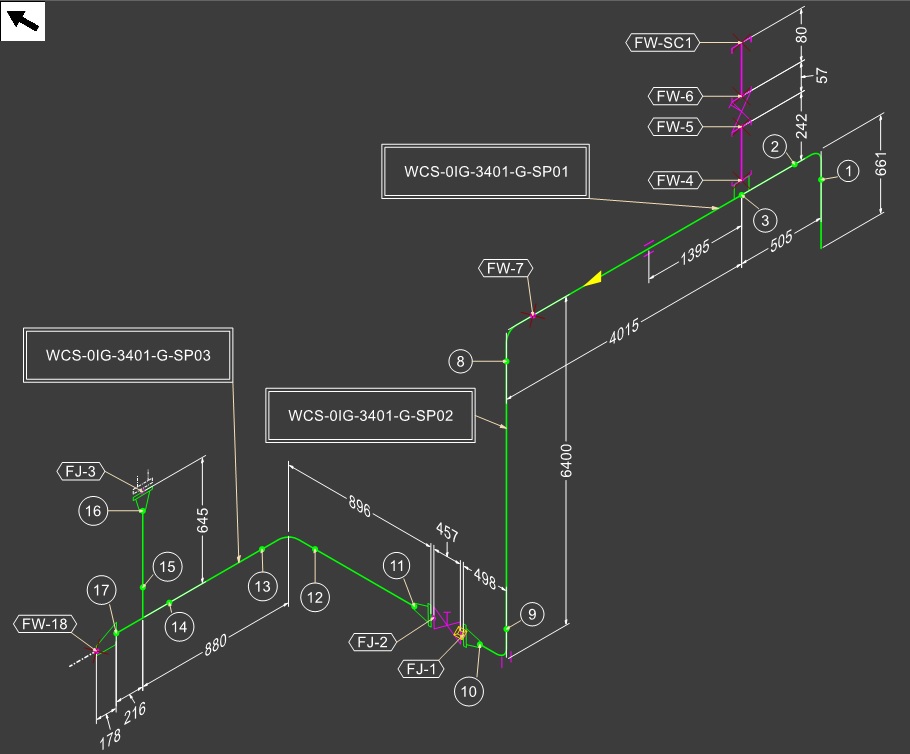

Simplify Piping Spooling operations by Auto Spooling, identify Shop & Fields Welds for the convenience of construction

Automatic Piping Spooling Software for Increased Efficiency and Accuracy

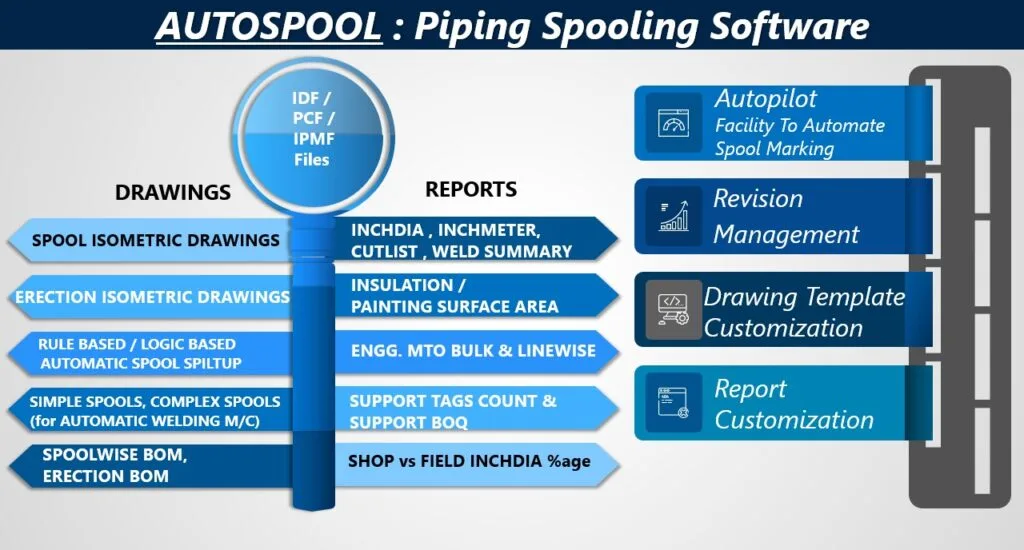

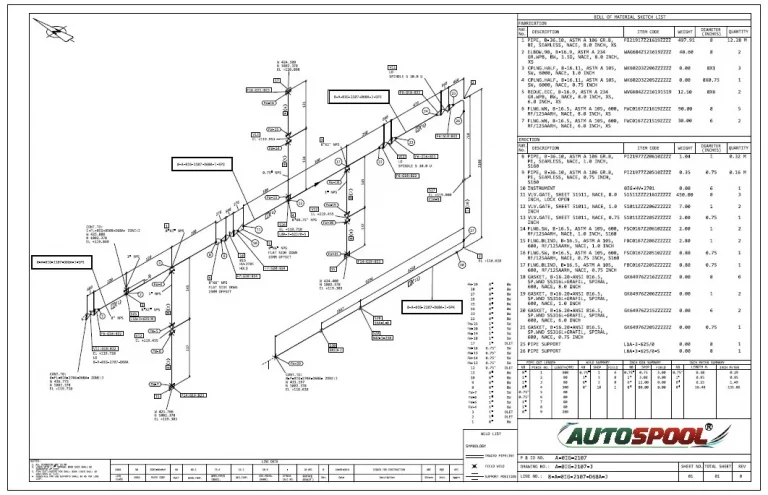

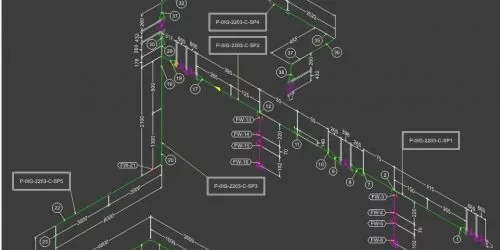

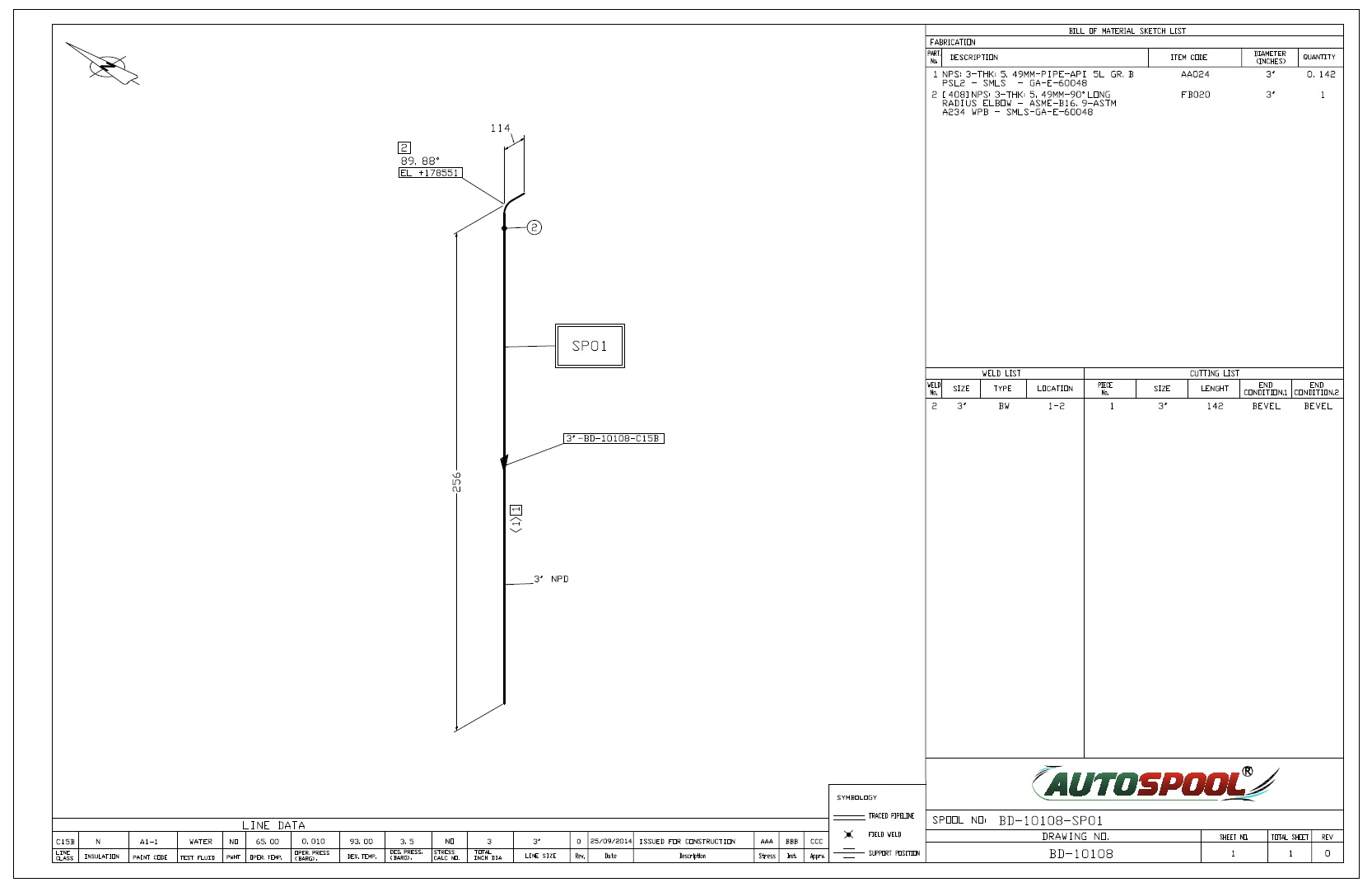

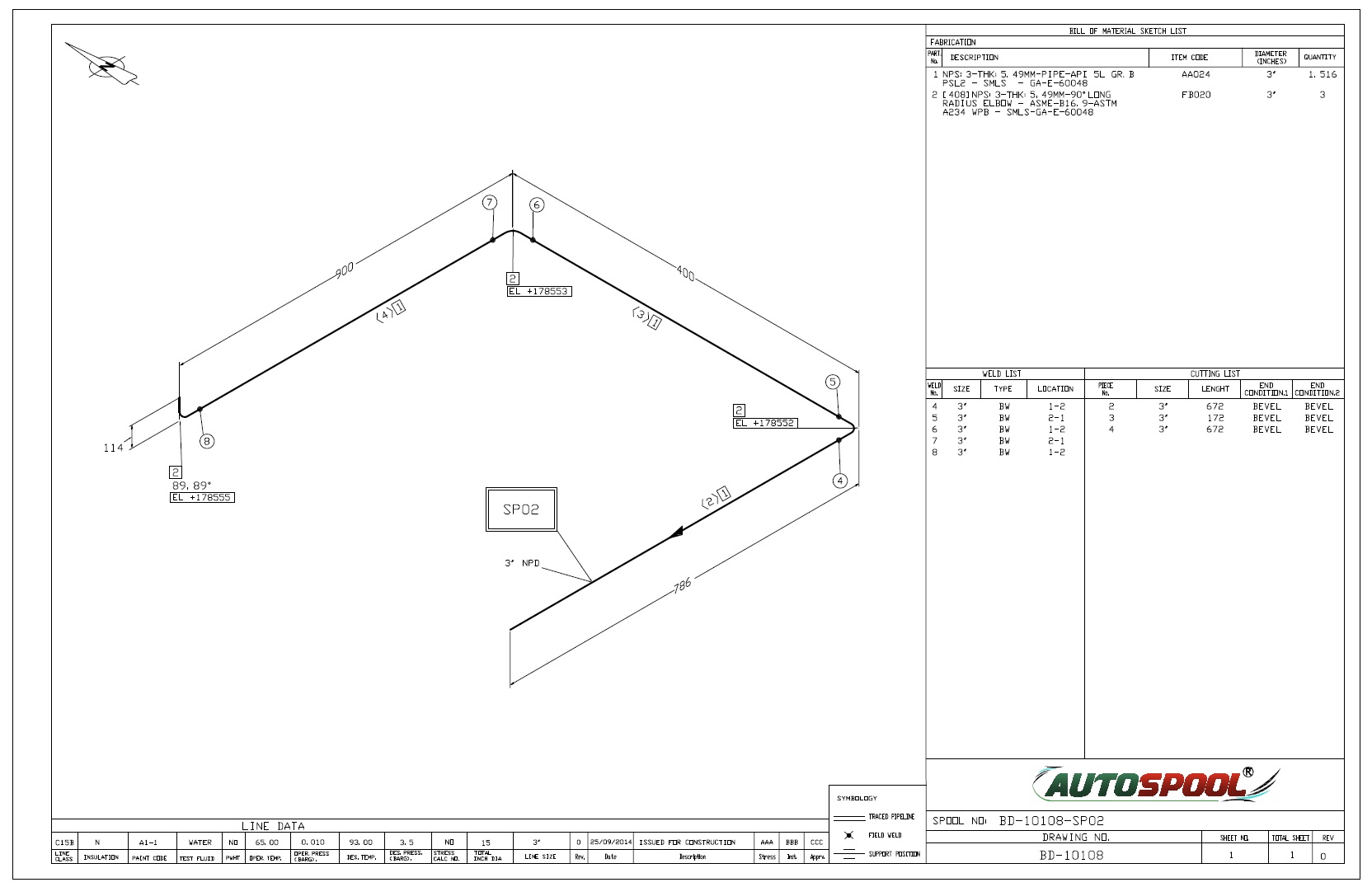

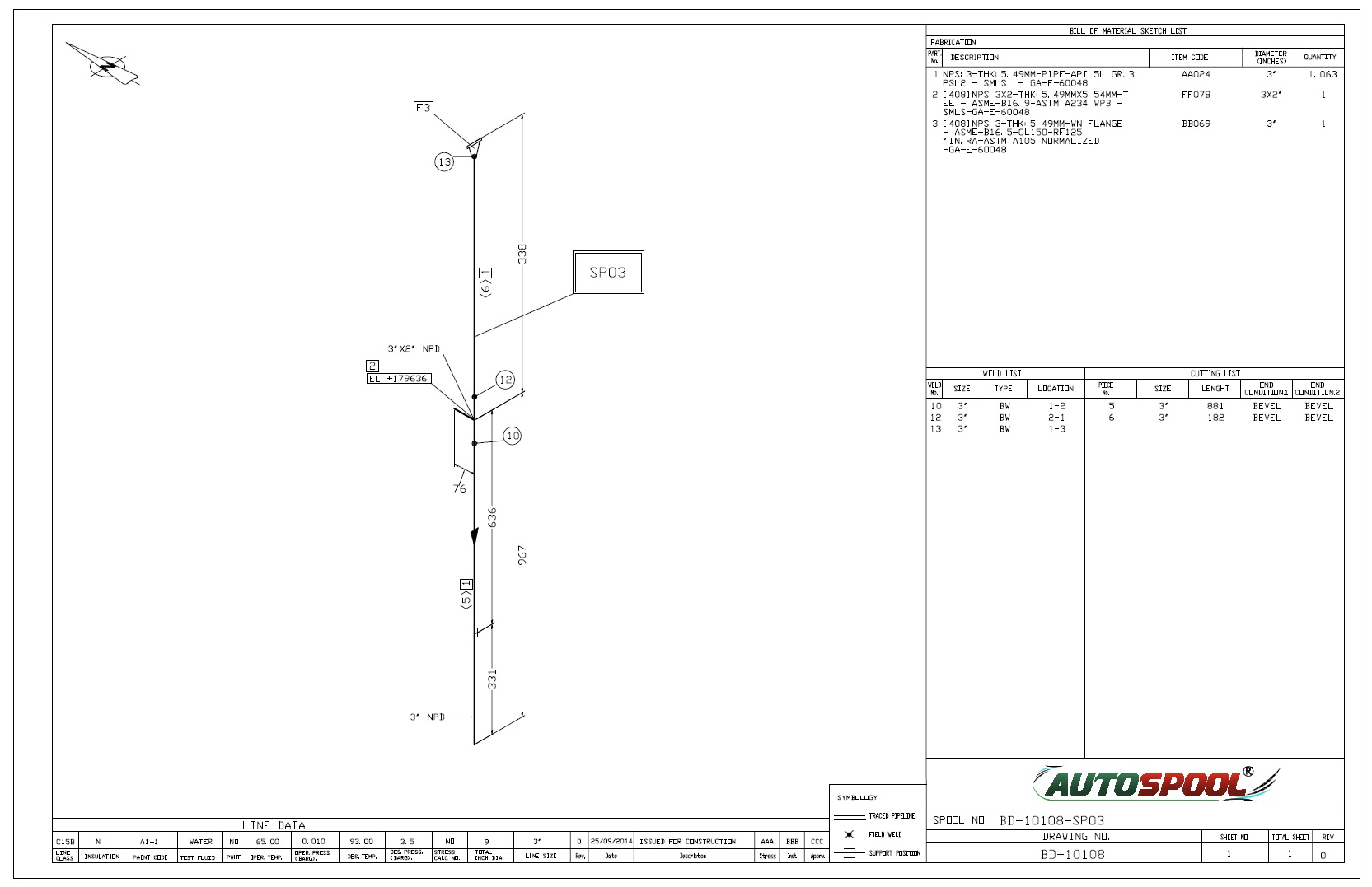

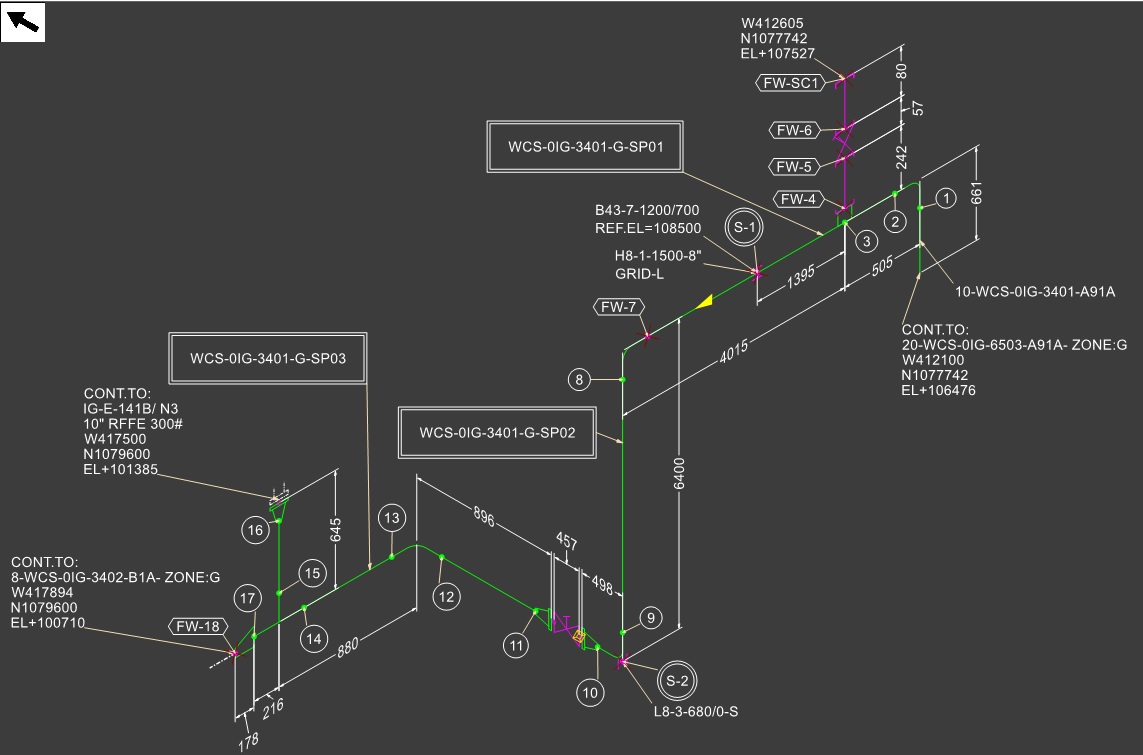

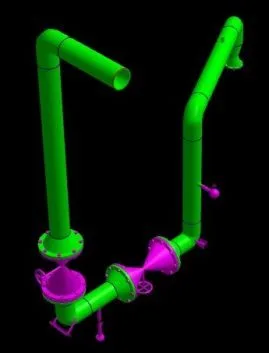

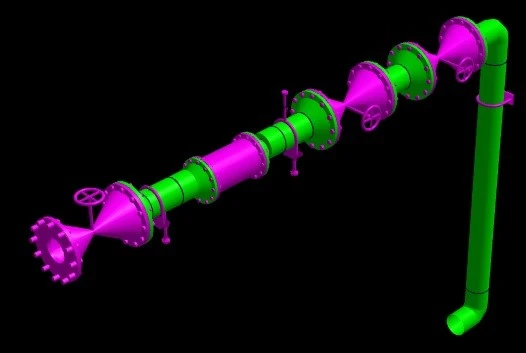

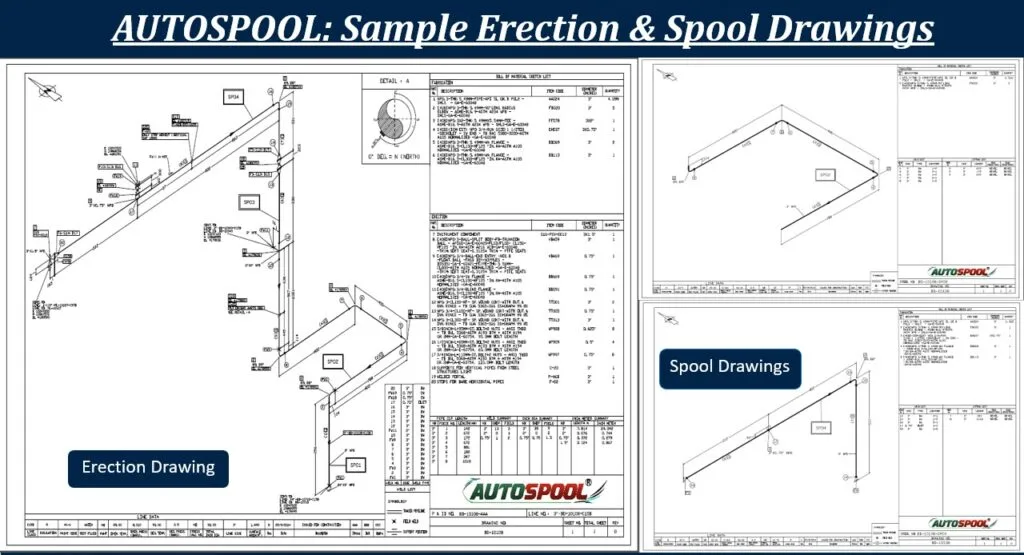

AUTOSPOOL is a powerful automatic piping spooling software that helps you generate piping fabrication, erection isometrics, and related reports quickly and accurately. It takes into account the convenience of fabrication and erection work, site requirements, and spool transportability to ensure that your projects meet the best international construction practices and client requirements.

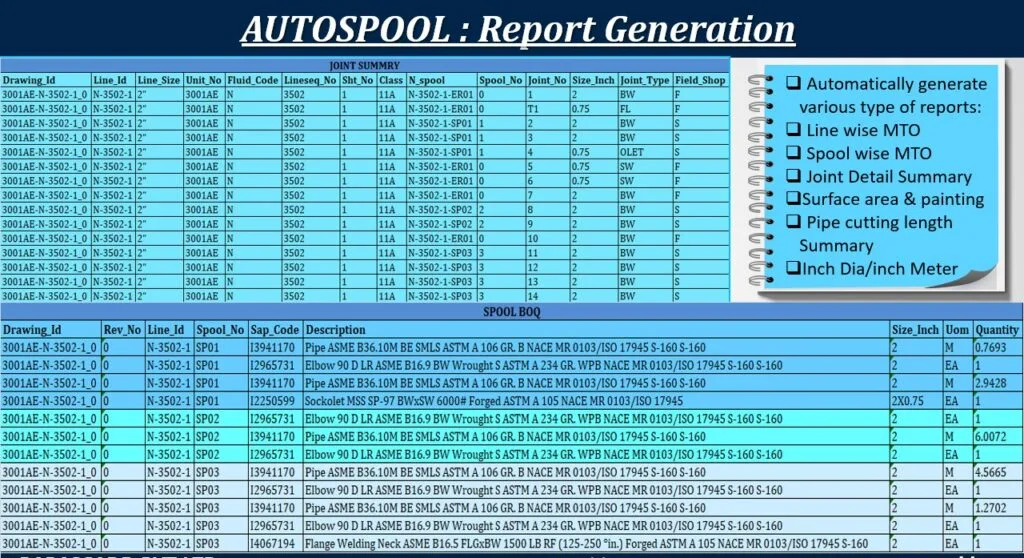

AUTOSPOOL generates construction scope in inch diameter, inch meter, and tonnage, and calculates piping cut length, piping bending length, spool weight, and surface area as required. This comprehensive functionality helps you streamline your workflow and reduce errors, resulting in significant time and cost savings.

Key Features of AUTOSPOOL

- Automatic generation of piping fabrication, erection isometrics, and related reports

- Considers convenience of fabrication and erection work, site requirements, and spool transportability

- Generates construction scope in inch diameter, inch meter, and tonnage

- Calculates piping cut length, piping bending length, spool weight, and surface area

Benefits of AUTOSPOOL

- Streamlined workflow

- Reduced errors

- Significant time and cost savings

- Improved efficiency and accuracy

- Increased confidence in project outcomes

Watch AUTOSPOOL in Action

AUTOSPOOL Brochure

Read how AUTOSPOOL helps you to generate piping Fabrication, Erection Isometrics & related reports.

Ease of Implementation

AUTOSPOOL + SPOOLMAN/ERMAN: Comprehensive Piping Project Management

AUTOSPOOL and SPOOLMAN/ERMAN can be integrated to provide a comprehensive solution for piping project management. SPOOLMAN/ERMAN provides activity-level project management, planning and control, progress monitoring, material management, and reporting for all stages of piping fabrication, erection, testing, flushing, box-up, warehousing, pre-commissioning of systems, and commissioning of units/plants.

- Improved efficiency and accuracy

- Reduced costs

- Increased visibility and control

AUTOSPOOL and SPOOLMAN/ERMAN are a powerful combination that can help you to successfully manage your piping projects.

AUTOSPOOL Features

AUTOSPOOL is a state of the art, Highly successful, software technology.

We have delivered a lot of value to our customers, via this product.

Customize it to Your Use

AUTOSPOOL: Fully Customizable Piping Spooling Software for Your Unique Needs

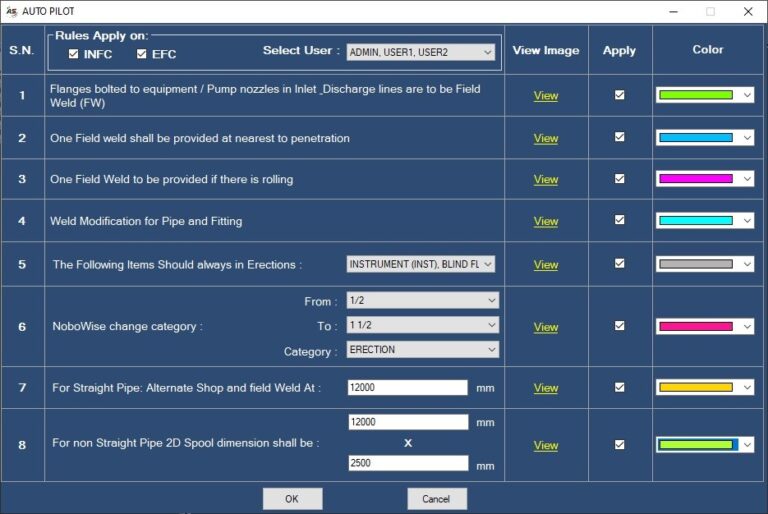

AUTOSPOOL is a highly customizable piping spooling software that can be tailored to meet the specific requirements of your business. Whether you need to integrate AUTOSPOOL with your existing processes, customize the output formats, or create a unique spool numbering system, AUTOSPOOL has you covered.

Here are some specific examples of how AUTOSPOOL can be customized:

- Output customization: You can customize the appearance and content of all AUTOSPOOL output, including graphics, bills of materials, and reports. You can also create custom output formats to suit your specific needs.

- Drawing template customization: You can customize AUTOSPOOL drawing templates to include your company branding, logos, and other required information. You can also create custom templates for specific types of drawings, such as isometric drawings, fabrication drawings, and erection drawings.

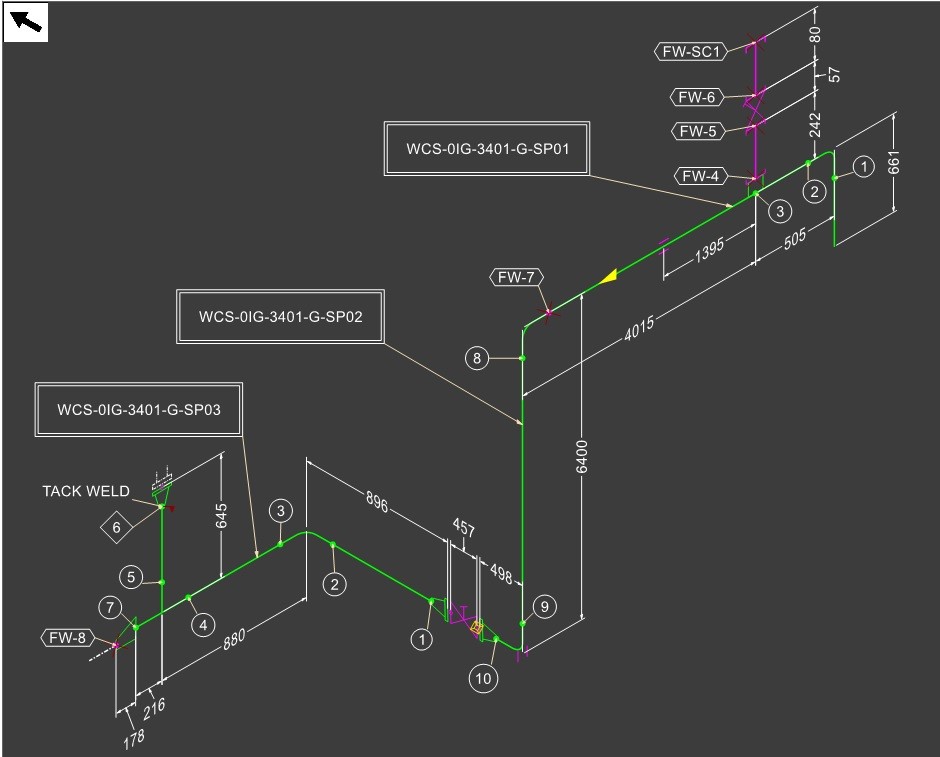

- Spool numbering customization: You can customize the AUTOSPOOL spool numbering system to match your existing system or to create a new system that meets your specific needs. You can also define custom spool numbering rules to ensure that spool numbers are assigned consistently.

- Weld numbering customization: You can customize the AUTOSPOOL weld numbering system to match your existing system or to create a new system that meets your specific needs. You can also define custom weld numbering rules to ensure that weld numbers are assigned consistently.

- Weld setting customization: You can customize the AUTOSPOOL weld setting to match your welding procedures and specifications.

- Weld identifier customization: You can customize the AUTOSPOOL weld identifier to include additional information, such as the welder's name, the welding date, and the welding process used.

- Weld category customization: You can customize the AUTOSPOOL weld category system to match your company's classification system.

- Reporting customization: You can customize AUTOSPOOL reports to include the specific information that you need. You can also create custom reports to meet the specific requirements of your clients.

...with Inch Dia. calculation considering reinforcement pad, branch connection, O-lets & other measurement factors

Generate or Read 2D, 3D barcodes

AUTOSPOOL Barcode Generation: Efficient Spool Tracking

AUTOSPOOL automatically generates 1D or 2D barcodes on piping drawings, which can be scanned to track spool status throughout fabrication and erection. This improves efficiency, reduces errors, and increases visibility.

Benefits:

- Improved efficiency

- Reduced errors

- Increased visibility

How it works:

- Select barcode type and data

- AUTOSPOOL generates barcode

- Barcode is automatically printed on drawing or generated separately

- Barcode is scanned to track spool status

- Data is used to update project management system

AUTOSPOOL barcode generation is a powerful tool for improving the efficiency, accuracy, and visibility of your spool tracking process.

Optimize Pipe Cutting

Automated Pipe Cutting Optimization

AUTOSPOOL software generates the most efficient way of cutting pipe, based on required cutting lengths and available pipe materials.This minimizes pipe wastage and effectively utilizes materials.

All cutting reports are generated automatically and can be sent to the pipe cutting machine for additional customization.

Benefits:

- Reduce pipe wastage

- Effectively utilize materials

- Automate pipe cutting optimization

- Generate cutting reports automatically

Estimate Consumables & Manpower

Precise Consumable and Manpower Planning

AUTOSPOOL generates precise consumable and manpower plans for piping fabrication and erection, based on the input available. This helps to ensure that you have the right materials and resources on hand to complete your projects on time and on budget.

Benefits:

- Accurate consumable planning

- Optimized manpower planning

- Reduced costs

- Increased efficiency

See Updates in 3D

AUTOSPOOL: 3D Model Progress Tracking

AUTOSPOOL, when integrated with SPOOLMAN/ERMAN, shows actual progress of fabrication, material availability, and erection in the 3D model. This 3D DWG file can be viewed by any third-party tool for review.

Benefits:

- Real-time progress tracking

- Improved collaboration

- Reduced errors

Integrate with 3rd Party Software

AUTOSPOOL is Open to Integration for Efficient Workflows

AUTOSPOOL results can be sent to third-party software, such as CMM machines or custom in-house systems, for further communication. AUTOSPOOL is also integrated with EPCPROMAN modules like SPOOLMAN and ERMAN for fabrication, erection, manufacturing, and material management.

Benefits:

- Seamless data flow between AUTOSPOOL and other software

- Improved efficiency and productivity

- Reduced errors and rework

AUTOSPOOL Outputs

Use of AUTOSPOOL

- Automatic and accurate Spool / Erection drawings

- Reduction in the upright construction work by at least 15%

- Automatic reporting at spool-level, joint-level, component

- Systematized processes

- 75% saving in time

- Reduction of errors in the work process

- Complete control on the job

- Revision Management and Project Management

- Reliable in every aspect of the work

How does AUTOSPOOL software Work ?

AUTOSPOOL works with following inputs:-

Neutral file *.idf, *.pcf, *.impf which are generated from leading plant design software but not limited to PDMS, E3D, PDS, SP3D, AUTOPLANT, PLANT3D, ISOMEC etc.

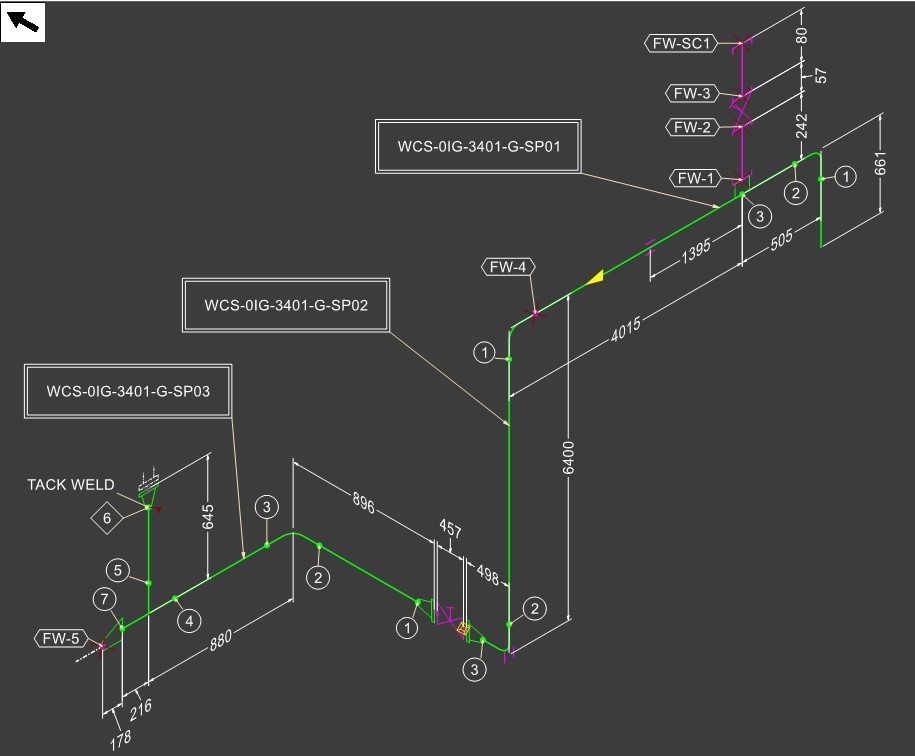

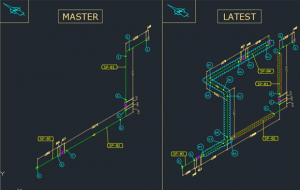

AUTOSPOOL Revision Management

AUTOSPOOL performs Efficient and Accurate Revision Management.

AUTOSPOOL revision management is a powerful tool for improving the efficiency and accuracy of your piping project workflow.

AUTOSPOOL efficiently manages piping isometric revisions, transferring changes from one revision to another and updating fabrication/erection management software. All changes are highlighted for easy identification.

- Efficient and accurate revision management

- Reduced errors

- Improved communication between engineering and fabrication/erection teams

Welding & Spooling

Efficient Welding Management for Construction Sites

Welding is a critical activity on construction sites, and proper planning can optimize project cost and schedule. AUTOSPOOL offers flexible options for efficient welding implementation, including:

- Combining multiple isometrics and adapting single isometrics to company standard welding criteria

- Optimizing field Inch Dia, locating field welds, and fixing field tolerance lengths

AUTOSPOOL helps to improve the efficiency of shop and field weld management, resulting in significant cost and time savings

Support Weld, Instrument & Other Components

Comprehensive Support Fabrication and Erection Management

AUTOSPOOL supports the detailing of standard library items, including support fabrication drawings and related MTOs. It also helps you plan for welding specific primary supports along with spools.

In addition, AUTOSPOOL can manage welding preparation details, instrument and special component installation, and fabrication and erection details of instruments, supports, and other special tagged items.

- Comprehensive support fabrication and erection management

- Improved efficiency and accuracy

- Reduced errors and omissions

- Increased visibility and control