PROCCPL

Cross Country Pipe Line Software

- On Cloud

- On Premise

Full Specifications

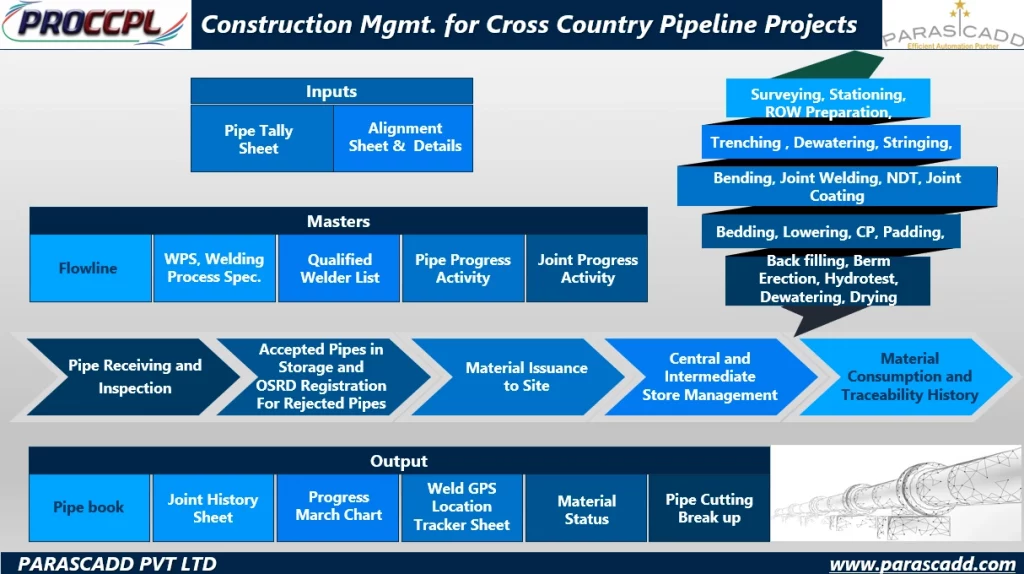

PROCCPL is a software for monitoring & Controlling Cross Country Pipeline projects.

PROCCPL can manage cross country pipeline project construction aspects such as:

- Manages the progresses with Alignment Sheet and Pipe Tally Sheet details

- Material / Pipe inspection and receiving at central / designated store, maintaining OSRD register

- Pipe issuance to project site

- Material / Pipe transfer control between storage yards / locations

- Pipe level progress monitoring - (Receiving, Stringing, Welding, NDT, Lowering, Backfilling, Pipe bending etc.)

- Joint level progress updation including – Fit-up, Welding, NDT, PWHT, Hardness Test,

- Hydro test, Cleaning /Gauging, Filling, Dewatering, Drying etc.

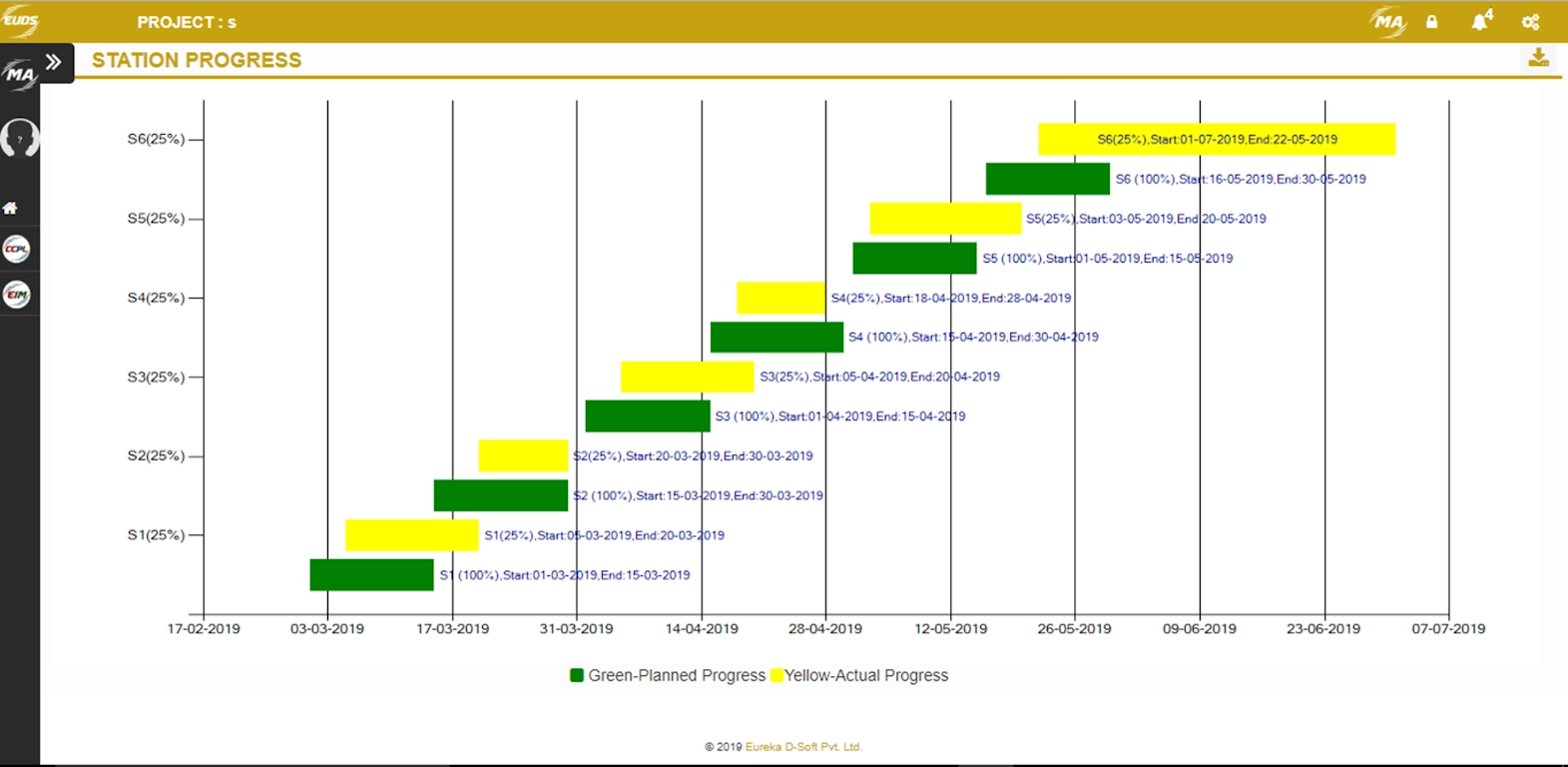

- Chainage, Section and Station wise level progress monitoring and reporting

- Archiving of Pipe Book and Joint History etc.

- Input

- Pipe Tally sheet from pipe supplier

- Alignment Sheet

- Output

- Pipe Book

- Joint History Sheet

- Progress reports

- March charts & record documents etc.

Scope of Project Cross Country Pipe Line Software

Scope of inputs

- Import Alignment Sheets with details related to Pipes, coating, and crossings.

- Import Tally sheet Details

Alignment Sheet

Alignment Sheet containing details of

- Pipes, Pipe material specification, pipe wall thickness, Type of coating on pipe & pipe – pipe welds.

- Start Point & Endpoint of Pipe thickness Change

- Crossing details with reference chainage location, Type of Crossings like Underground piping / Above Ground Piping, Cable Crossing, Track, Electrical crossing, etc.

- Bend details like Bend angle, Cold/Hot bend, Type of bend (Horizontal/Vertical) & IP reference, etc.

Tally Sheet

Pipe Tally Sheet contains details of pipe delivered from Pipe Supplier/manufacturer containing

- Pipe Size & Wall thickness

- Pipe material specification

- Material Traceability information like Heat Number/Bundle reference

- Pipe length

- Pipe supplier name/reference code etc.

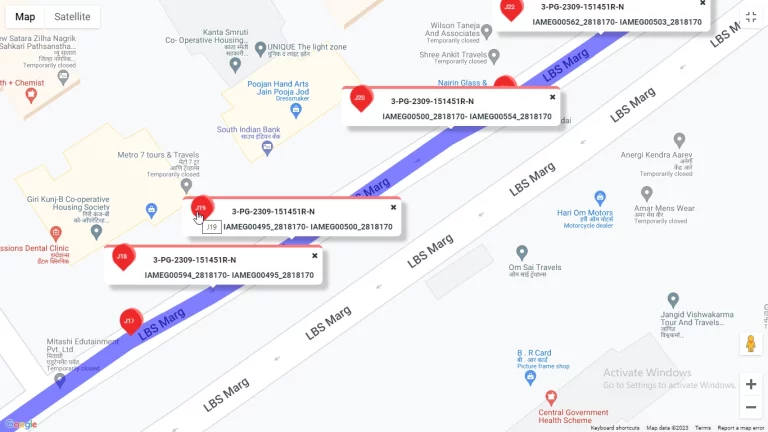

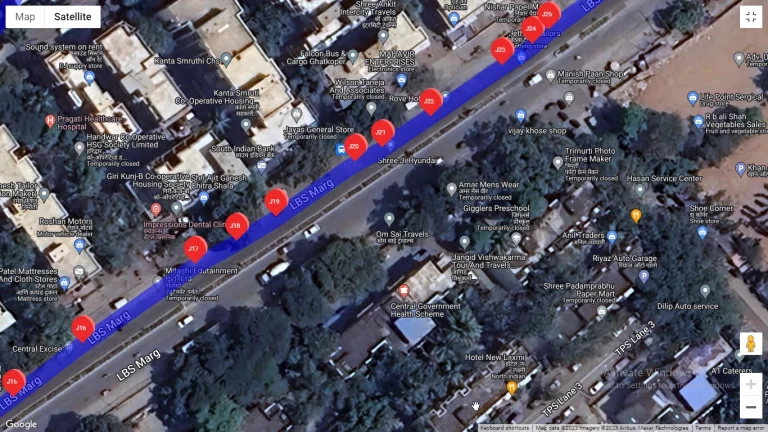

Presenting Graphical Data and Dashboards for an Insightful Overview

Quality Control

- Defining Weld Joints on Flow line & the connecting Pipe Tags along the project route

- Joint sequencing along the project route

- Welder qualification & maintaining welder master data with expiry dates

- Maintaining WPS & Welding process masters

- Performing Joint level Fitup

- Welding of Joints & capturing welding details like

– WPS, Welding process,

– Welding passes (ROOT / HOT / FILL / CAP)

– Weld location ( ROW / TRENCH / TOP

Material Issue Voucher

Pipes are issued to Work site through MIV’s (Material Issue Voucher), where pipe count,pipe length,Store location are recorded & controlled.

Provision for transferring pipes from one storage location to other storage location is also controlled.