CIVILMAN- STRUCTMAN

Unlocking Success in Structural and Civil Construction Management with EPC Project Management Control Software

STRUCTMAN : Construction Structural Activity Management Software

STRUCTMAN is used to Track, Monitor, Control, Analyze and Report Structural Steel progress at different stages like Tendering, MTO, Ordering, Manufacturing, Assembly, Erection, Variance, Reconciliation, etc.

Structural Assemblies are approved at engineering release level & released for fabrication after checking the joints, BOM, NDT & SR requirement, Painting, etc. Assembly drawings are released for fabrication through Documented Transmittal with Assembly wise tonnage & scheduled completion date for fabrication.

STRUCTMAN is a software solution for managing structural activities on construction sites. It helps users to efficiently manage all aspects of structural assembly fabrication, including:

- Engineering material control and planning

- Production

- Welding

- NDT (nondestructive testing)

- Painting

- Laydown and dispatch

Key Features of CIVILMAN-STRUCTMAN

- Inventory control and management of all structural items, along with comprehensive summary reports

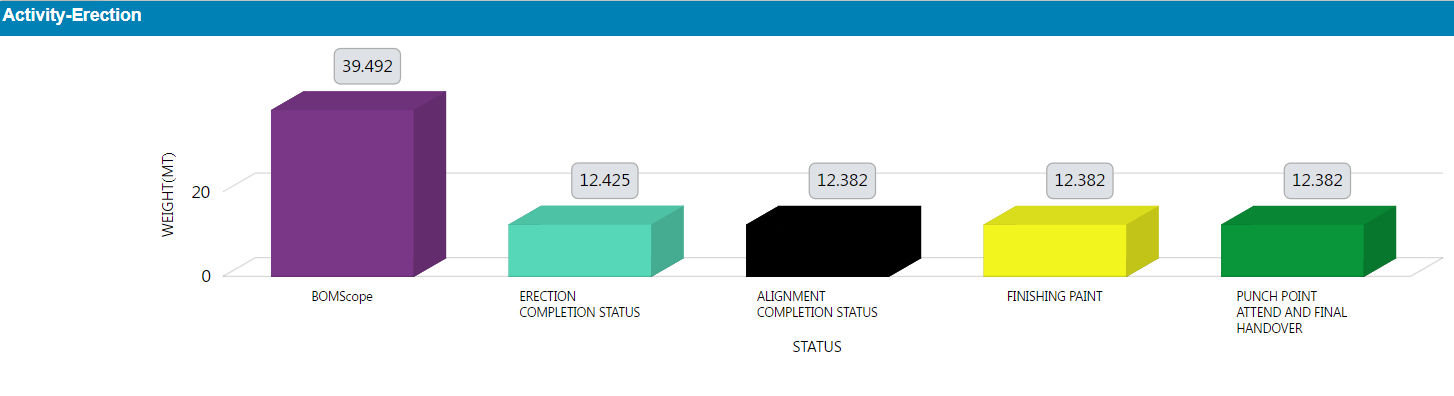

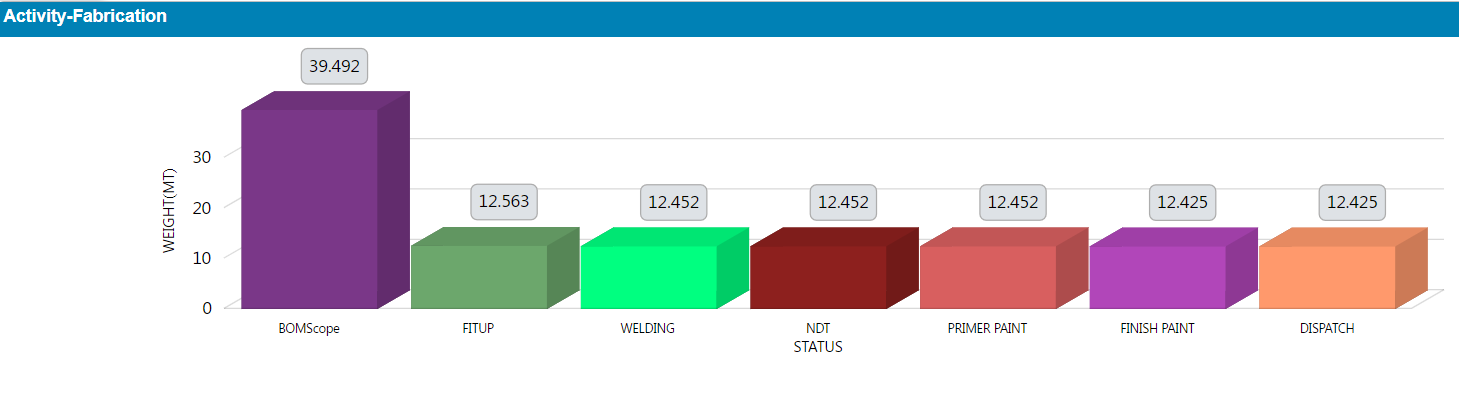

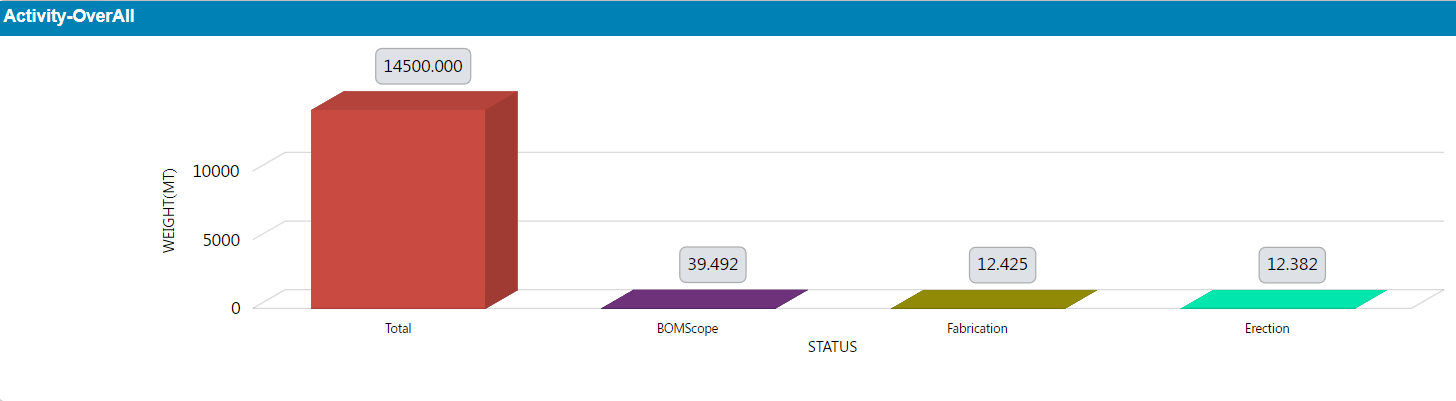

- Dynamic Progress Monitoring: Real-time tracking at fabrication and erection sites, categorized by activity type, assembly/element level, and item code for detailed progress analysis.

- Joint-wise Fabrication Tracking: Monitors each stage of the fabrication process, including fit-up, welding, NDT (Non-Destructive Testing), and painting—on a joint-wise basis to ensure quality and accountability

- Erection Process Oversight: Comprehensive monitoring of the erection workflow, covering contractor issuance, structural assembly, and the erection of individual parts

- Mobile-enabled Progress & Inventory Tracking: Field-friendly mobile applications equipped with barcode and RFID scanning for efficient, on-site progress and material tracking

- Revision Management & Progress Transfer: Seamless migration of progress data for assemblies and joints across revisions, ensuring continuity and data integrity throughout structural changes

- Dashboard and other management-level reports for effective project oversight and decision-making

Benefits of CIVILMAN-STRUCTMAN

- Increased efficiency and productivity: STRUCTMAN automates many of the time-consuming tasks involved in managing structural activities, such as material tracking, scheduling, and reporting. This can help users to save a significant amount of time and effort.

- Reduced errors: STRUCTMAN's centralized database and automated workflows help to minimize the risk of human error.

- Improved visibility and control: STRUCTMAN provides users with a real-time view of all structural activities, giving them the visibility and control they need to make informed decisions.

Activities in Structural Management

- Inventory Control and Management of all structural items.

- Summary of MTO/PO/MRR/MIV QTY.

- Fabrication process like Fitup / Welding / NDT/ Painting monitoring

- Erection process like Contractor Issuance /Assembly and Parts erection monitoring.

- All the Progress and inventory tracking via Barcode and RFID scanning through Mobile apps.

Optimizing Structural Work Progress Tracking and Reporting

- Structural Fabrication

- Erection Management

- Material Management

- Material Reconciliation

- Progress Monitoring

- Backlog/shortage analysis

- PROJECT WBS Definition (WBS / units etc.)

- SCOPE / Breakup Quantity in terms of MT & No's (as per WBS. Unit, GA, FAB. Drg. etc.)

- Input data can be loaded from TEKLA MODEL (xml file)/ source data can be in excel

- Dynamic Definition of Progress Activities & Activity level monitoring

- Assembly Level / Member Level Control

- Progress Trend charts, Weekly / Monthly Reporting

- Billing, RFID & BARCODES / Mobiles Apps for automation & online working

- Material Issuance (MIV), Material Return (MRV) & Reconciliation

- Possibility of Weld Joint / Bolted Joint level monitoring

Track-N-Tracing Mobile app for Efficient Inventory Management: Usage workflow for Structural and Civil Construction.

Effortlessly streamline construction site inventory management with our cutting-edge product, Track-N-Tracing.

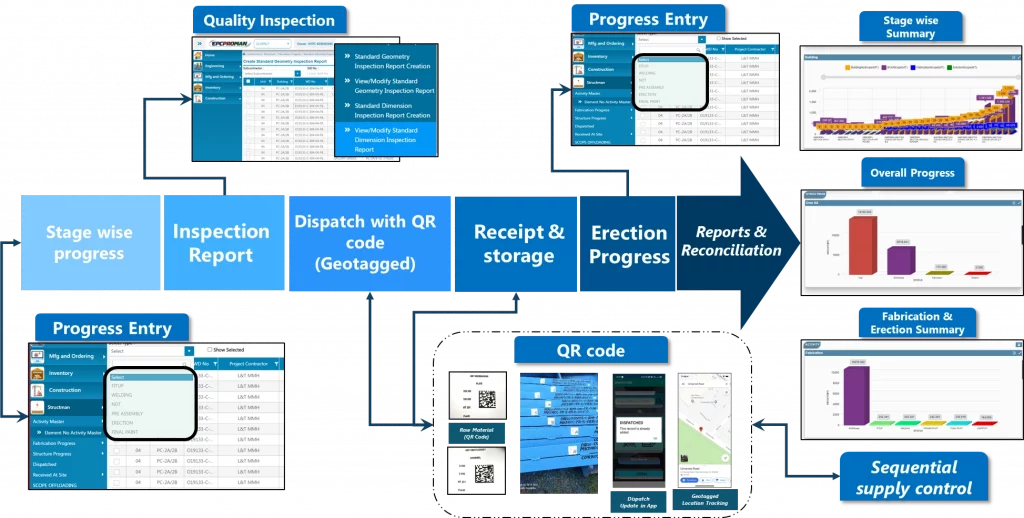

STRUCTURAL Workflow

TRACK INVENTORY AND ASSEMBLY PROGRESS VIA GOOGLE MAP

Structural Fabrication & Erection Monitoring

The Structural Workflow Process

CIVILMAN-STRUCTMAN Brochure

Discover how CIVILMAN-STRUCTMAN can help you manage civil construction activities more efficiently and effectively.

Progress Dashboards

STRUCTMAN FAQ

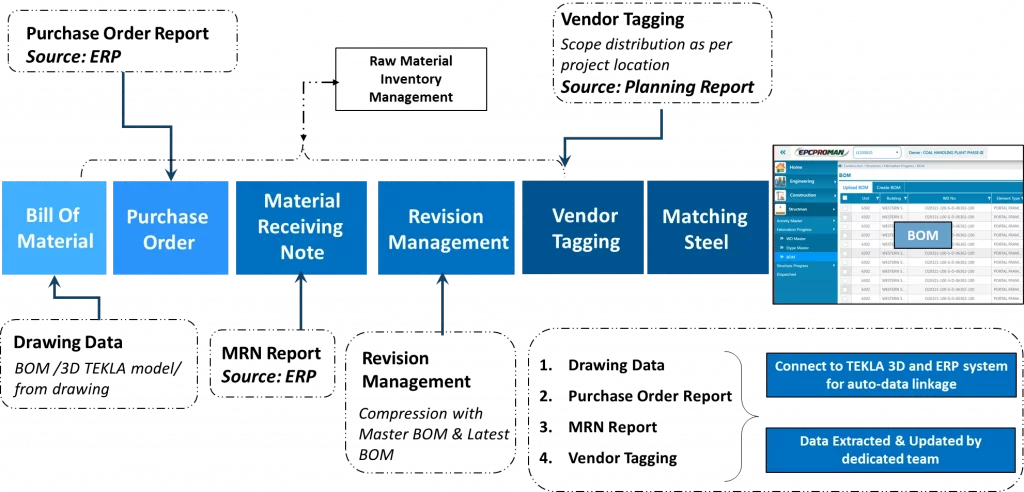

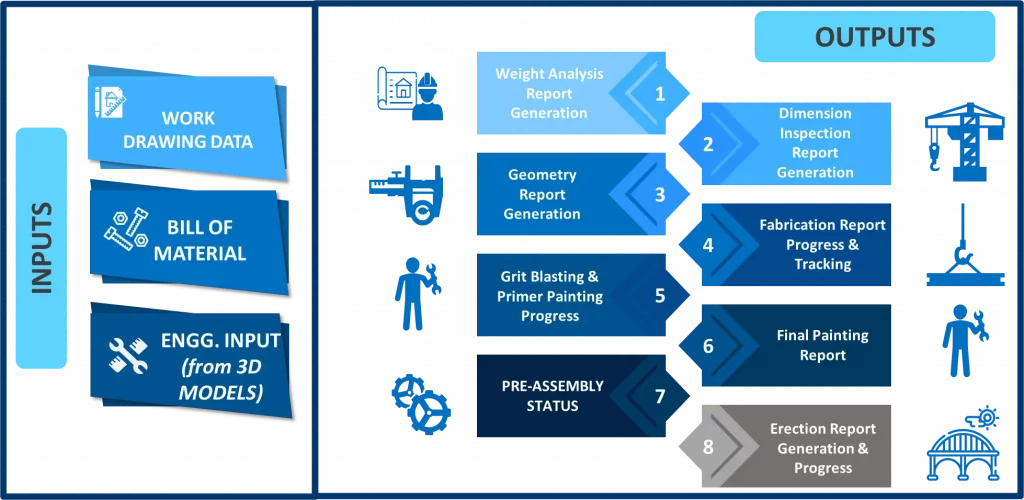

- This software offers a comprehensive solution for Structural Fabrication, covering the entire process from drawings to erection completion. It consolidates all fabrication data into one platform, including:

- Bill of Materials (BOM) derived from drawings

- Purchase Orders (PO) and Material Receipt Notes (MRN) from ERP systems

- Onboarding of fabrication subcontractors in the yard or outsourced fabrication vendors, including drawings and material allocation

- Progress tracking of fabrication stages

- Inspection records for each stage

- Dispatch control with QR codes

- Receipt and storage control at the site with QR codes, providing benefits to the customer

- Progress tracking of erection stages, also benefiting the customer

- When this software is implemented, all stakeholders involved in the process, such as TGS, Design Agencies, Fabrication Vendors, Yard-based Subcontractors, and Customers, will be on the same page.

- The software generates automated reports with micro-level data, allowing you to:

- Generate a Matching Steel Report, comparing the balance BOM with the balance raw material (RM)

- Prioritize allocation based on urgency

- Generate a partial matching report, indicating the steel that needs to be procured

- Allocate higher sections as needed

- Access an online live Daily Progress Report

- Identify surplus raw material, enabling decisions for re-allocation

- Manage subcontractor and vendor billing

- Facilitate client invoicing

- The gaps themselves may not be the focus, as each customer may require customization due to varying process flows.

- Customization is also necessary to accommodate different ERP systems for seamless direct connectivity through API, such as for connecting to PO/MRN (steel), DC (FG), Subcontractor Billing, etc.

The greatest advantage in raw material and inventory management can be achieved through the following methods:

- Utilizing QR code-based tracking for both the mother plate and child QR codes for cut pieces, enabling tracking of off-cuts.

- Integrating Bill of Materials (BOM), Purchase Orders (PO), and Material Receipt Notes (MRN) in the same database, allowing for the generation of live automated reports:

- Surplus steel can be effectively managed by comparing the balance of raw material with the balance of the BOM.

- Partial Matching Reports can assist in determining the minimum amount of steel to purchase in order to maximize matching with existing steel.

- Reconciliation reports can be generated to ensure accurate inventory records.

- Inventory aging analysis can be conducted to identify and address any obsolete or slow-moving inventory.

- By incorporating cost data into the software, a report on inventory carrying costs can also be generated.

It should be noted that this software will not directly lead to an improvement in throughput and production.

However, this software can serve as a facilitator for ensuring optimal loading of the shop based on the available data, which in turn enables completion and dispatch according to the specified marks. This maximizes production capacity.

Additionally, the software helps in reducing labor and asset idling.

Furthermore, it helps in minimizing losses and rework caused by drawing revisions, as these are controlled through the software.

- In terms of project management, the end customer will have the ability to monitor progress online, prioritizing projects as needed. Access to the software will be provided.

- The use of QR codes on received materials will enable efficient tracking, ensuring effective storage and control.

- The end customer will also have the capability to utilize the same module for monitoring erection progress at each stage.

Key Features of EPC Project Management Control Software

for Structural and Civil Construction

Engineering

- Intelligent way of Coding of all Structural Steel Items

- The software has Facility / Provision to upload Tender, MTO and AFC Qty. for Structural Steel items.

- Engineering MTO Analysis w.r.t Tender as well as AFC Qty. (Approved for Construction) at item level.

- Generation of Summarized Report in Tabular Form for comparison of Tender, MTO & AFC Qty.

- Generation of Variance Statement for Management Approval to manage the Contracts as per terms and conditions. It will also help in updation of Estimated Budget, Budget Forecast, and Cost Control.

- Facility to upload Structural Master Data with break-up details like WBS number, Unit No., GA Drg. No., Fabrication Drg. No., Assembly No., No. of Assemblies, Weight of Assembly and so on.

Procurement

Provision to define Procurement activities like;

- MR

- RFQ

- Bid Receipt

- Evaluation

- Recommendation

- Order Placement

- Inspection and Testing

- Manufacturing & Delivery

Shop Fabrication, Assembly & Delivery

Provision to define Structural Fabrication and Assembly activities like;

- Sub-ordering of Materials (if applicable)

- Receipt of Materials

- Manufacturing

- Assembly

- Inspection and Testing

- Despatch and Receipt at Site

Erection at Sites

Provision to define Structural Erection activities like;

- IRN (inspection release note for Assemblies fabricated by Fabrication Contractor)

- Material Shipped / Dispatched from Structural Fabrication Contractor

- Material Received at Site (receipt of fabricated Assemblies at site)

- Material Issued (issuance of fabricated Assemblies to Erection Contractor)

- Erection of Assemblies

- Alignment, Grouting & Bolting

- Fire Proofing

- Painting

- QC final clearance etc.

Project Control Activities

- Progress monitoring on Quantitative / Efforts (Man-hour) / Cost basis

- Activity-wise Planning, Scheduling, Monitoring and Progress Reporting

- Reporting at different levels like WBS, Unit and Complex levels, with activity-wise breakups with Trends / Profiles

- Calculation of %age Progress for each phase with Forecast / Curves

- Generation of reports in .xlsx, pdf,.txt formats for ease of customizing

Tracking and Monitoring Through RFID / Barcodes

Latest RFID / Barcode Technology can be used for Tracking and Progress Monitoring at various stages like;

- Receipt of Fabricated Assemblies at Sites

- Allocate Storage Space to Assemblies and identify Location

- Issuance of Fabricated Assemblies to Erection Contractor

- Erection Progress etc.

Output reports

- Fitup report

- Welding report

- NDT report (RT,UT,DPT,MPT)

- Structure history sheet

- Painting

- Laydown report

- Dispatch report

- Progress review report

- Welder performance report

CIVILMAN: Construction Civil Activity Management Software

CIVILMAN is a software solution for managing civil construction activities on construction sites. It helps users to efficiently manage all aspects of civil structure construction, including:

- Earthwork

- Piling

- Concreting

- Masonry and plastering

- Flooring

- Waterproofing

- Doors/windows

- Painting

- Other miscellaneous works

Benefits of CIVILMAN:

- Increased efficiency and productivity: CIVILMAN automates many of the time-consuming tasks involved in managing civil construction activities, such as material tracking, scheduling, and reporting. This can help users to save a significant amount of time and effort.

- Reduced errors: CIVILMAN’s centralized database and automated workflows help to minimize the risk of human error.

- Improved visibility and control: CIVILMAN provides users with a real-time view of all civil construction activities, giving them the visibility and control they need to make informed decisions.

CIVILMAN is a powerful tool that can help users to improve the efficiency, accuracy, and visibility of their civil construction activity management process. It is a valuable tool for any construction company that wants to save time and money on its projects and deliver high-quality results to its clients.

Civil structures are logically divided into structural items, such as foundations, pedestals, columns, beams, slabs, walls, and floors and ceilings. Each item has a reference number, grid location, elevation position, and status. The status of construction activities is recorded daily in the system. The stage-wise progress of individual civil structural items is recorded and monitored to allow for the start of the next level of activity.

Output reports

- Monitoring the status of activity completion for civil structural items

- Creation of reports for activity completion of civil structural items

- Generation of List of activities completed for Main Civil structure

- Generation of List of activity pending for completing Main Civil structure

- Reports of activity Schedule data & actual completion date

- Reports of estimated quantum & actual quantum of work as per data of construction completion