MATCONTRK

Material Analysis & Look Ahead Plan

- On Cloud

- On Premise

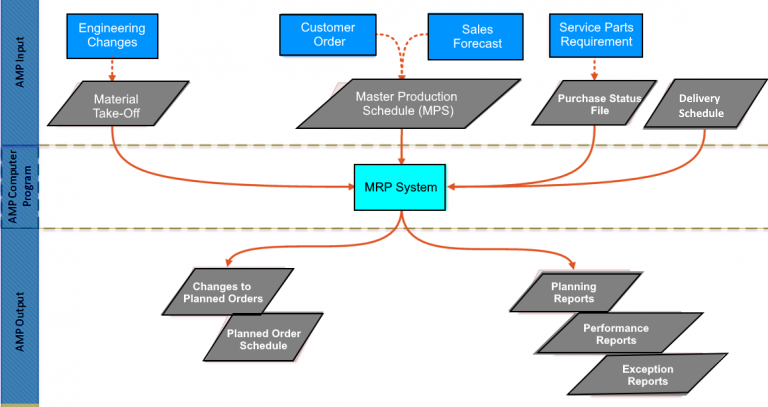

MATCONTRK is a specialized module within the EPCPROMAN suite, developed by PARASCADD, specifically designed to streamline material control and facilitate proactive look-ahead planning for Engineering, Procurement, and Construction (EPC) projects.

Key Features of MATCONTRK

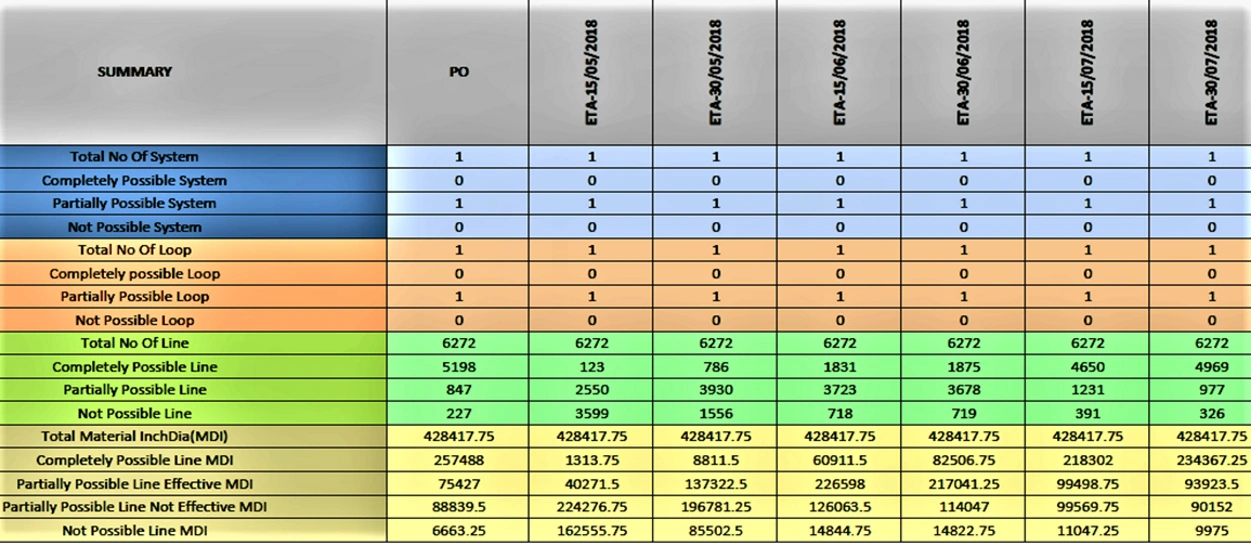

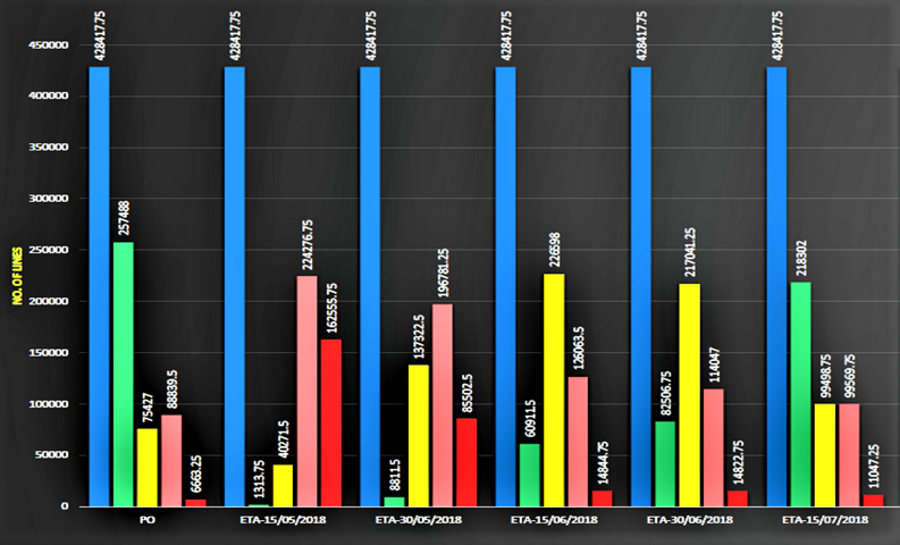

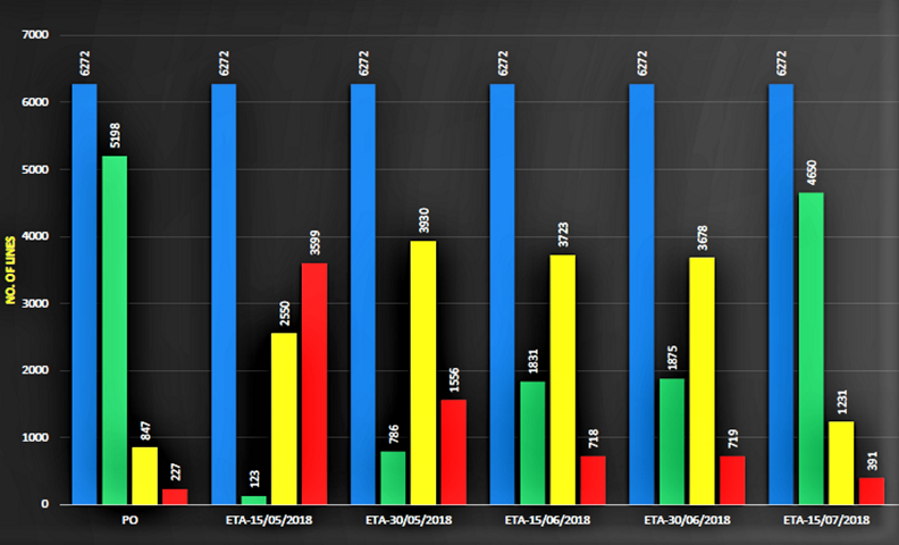

- Analysis and reports are provided for MTO vs. PO/CDD/ETA/Transit/DRR/MRR

- Generates a list of lines with fully available materials

- Generates lists of lines with partially available materials or no availability at all

Benefits of MATCONTRK

- It will help EPCM/EPC/Fabricator to plan the work properly

- Make proper deployment plan for manpower & machinery

- Ensure optimum utilization of resources

Beneficiary Organization

EPCM/EPC/ Fabricator & Owner

Beneficiary Department

Project, Project Control, Procurement, Fabrication, Erection

MATCONTRK Brochure

Explore How MATCONTRK Facilitates Material Analysis and Look-Ahead Planning

Advantages of MATCONTRK

- MTO Analysis and find out effective Material Required Quantity

- Material Substitution, Stock Transfer

- Piping, Structural, Civil, Equipment, Electrical, E&I, HSE etc.

- Substitution, Stock Transfer, Effective Purchase Qty.

- Material Purchase Control, Raise PR, Raise PO

- Substitution, Stock Transfer, Effective Purchase Quantity

- Material Purchase Control, Raise PR, Raise PO

- Material Delivery Schedule Tracking, CDD, FDD, SRN, Transit

- Material Shortage, not delivered or Over received.

- Material available (Inspected) / (non-inspected)

- Material PO is placed, in transit (PO is raised)

- Material MTO from engineering

- PO vs. PR

- MTO vs. Purchased Quantity

- Ordered vs. Delivered Quantity