EPC for Qusahwira Field Development

A Case Study

EPC for Qusahwira Field Development Project Phase II.

Petrofac is a leading energy services company that helps our clients meet the world’s evolving energy needs. We use our engineering know-how and our consultancy expertise to design, build, and operate world-class energy facilities that are engineered for safety, optimal efficiency, and low emissions.

ADNOC (Abu Dhabi National Oil Company) is a leading diversified energy group taking transformative steps to make today’s energy cleaner while investing in the clean energies of tomorrow.

Contractor

Owner

We express our gratitude to the project team, Petrofac staff, and all the key stakeholders for their collaborative efforts in bringing this project to fruition.

Project Manager, ADNOC.

Industry: Private

Technology Leveraged:

Project Solution:

- EPCPROMAN Software

- Spool Drawings

- Piping Isometric Drawings

- Revision Control Management

- Piping Inventory and Tracking

- Fabrication Management

- Erection Activity

- Documentation and Reporting

- 3D Monitoring and Progress

- Mobile Compatibility

- Quality Control

The Client : Petrofac / ADNOC.

ADNOC is a leading diversified energy group taking transformative steps to make today’s energy cleaner while investing in the clean energies of tomorrow. Their network of fully-integrated businesses operates across the energy value chain, helping them to responsibly meet the demands of an ever-changing energy market.

Their Requirements

Project Scope

Solution & Approach

Our EPCPROMAN team implemented the Integrated Piping Management System for the EPC FOR QUSHAWIRA FIELD DEVELOPMENT PHASE II PROJECT. The effective implementation of the EPCPROMAN in the QUSHAWIRA project. The important elements for a project’s effective completion are listed below along with how EPCPROMAN helped in the completion of the project.

Improved Project Planning and Scheduling: EPCPROMAN software enables detailed project planning and scheduling, allowing projects to create comprehensive timelines, allocate resources, and set milestones. This leads to better project organization and efficient resource allocation.

Enhanced Collaboration: EPC projects involve multiple stakeholders, including engineering teams, procurement departments, construction crews, and more. Epcproman software facilitates collaboration by providing a centralized platform for data stores, documents, and real-time progress updates. This reduces the chances of miscommunication and improves teamwork.

Document Management: EPC projects generate a significant volume of documents, including engineering drawings, specifications, test packs, and reports like (Fit up, Welding, NDT). Epcproman software offers document management features that centralize document storage, reversion control, and access control, making it easier to manage the project documentation.

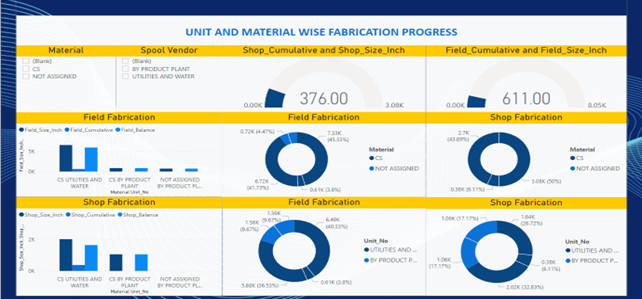

Real-time Tracking and Reporting: EPCPROMAN software provides us real-time tracking of project progress, which enables stakeholders to monitor project status like (Fabrication inch Dia completion & Erection completion), identify delays, and take corrective actions promptly. Customizable reporting features allow for the creation of comprehensive project reports and dashboards.

Streamlined Change Management: Changes are inevitable in projects, software helps manage change requests like (SCR, FCR and the revision control), assess their impact on the project scope and schedule, and implement changes in a controlled manner.

Project Objectives Achieved:

Piping Isometric Drawings: In our project, the system effectively executed robust drawing generation. We successfully completed the spooling for 16591 ISOs in a brief amount of time, meeting the deadline. Spooling production for our project was 300 ISO per day. We completed the spooling for 22372 ISO’s since we created the ISOs for revision, SCR, and FCR.

Piping Inventory and Tracking: The crucial component of our project that required good control was inventory management. For 5 contractors, we handled the material issuance and inventory control. We were handing out Job cards to the contractor for fabrication and erection. With the 50000-inch Dia job card that we gave to the fabricator ahead of schedule, we reached our first milestone, and the client was very appreciative for same.

We tracked and arranged materials for the crucial shutdown task three times throughout the project with the aid of the program. A weekly publishing was done pertaining to the material shortage list for the client and the project team.

Documentation and Reporting: The data (Fit up, Welding, and NDT reports), along with isometric drawings, test packages, and compliance welder certifications, could have been stored in a database that the client could access whenever he required. The client was happy with this since it now makes it easier for them to view all the signed reports in one location. We always delivered reports to client in accordance with their formats after collecting data from the system.

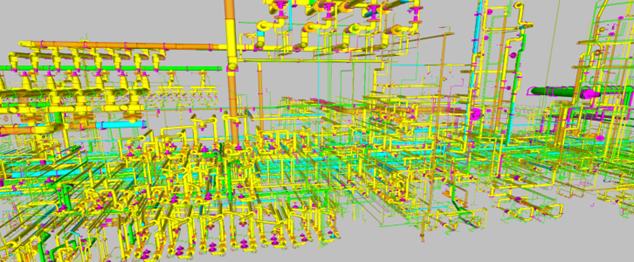

3D Monitoring and Progress: The project incorporated real-time monitoring to see the difference between Planned vs. Actual progress. In QUSAHWIRA project, 3D progress tracking was crucial in winning over the client. Through 3D visualization, the client constantly wants to see actual site development. According to the client’s request, we successfully integrated this in our project. The client management team was delighted that we exhibited and shared the 3D Model progress with them every week.

Key Deliverables:

Integrated Piping Management System: The core system, comprising modules for inventory management, documentation, monitoring, and reporting, was successfully developed and integrated.

QA/QC Requirements: Maintaining quality standards is essential in EPC projects, in our project; we followed the same we worked to meet the quality requirements and updated the data accordingly. We have submitted the required reports to the quality department like (Repair % list, NDT summary, NDT % wise report) Spec wise and completely able to trace material with the heat number, so we made sure they won’t face any challenges in the future.

User-friendly Interface: The system’s user interface was designed with usability in mind, ensuring that users can easily navigate and utilize its features without extensive training.

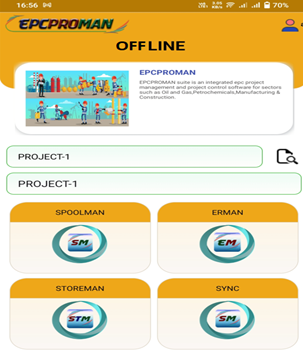

Mobile Compatibility: The systems were optimized for mobile devices; the same as we used in our project. We updated them offline progress in the system through the bar code scanning and it allowed us to update the progress in the system.

Factors affecting the successful execution:

A project must be carefully planned, communicated with, managed, and have several critical components aligned to be successfully completed. Here are some essential conditions for a project’s execution success, while exact needs may change depending on the project’s type and the sector:

Clear Project Goals and Objectives: The project must have well-defined goals and objectives that are specific, measurable, achievable, relevant, and time bound. This provides a clear direction and purpose for the project team. In our project, we were very clear in our head to get our results hence we identified and noted all the tasks before starting the project execution to make sure we don’t miss anything and can work keeping the objective in mind.

Detailed Project Plan: Develop a comprehensive project plan that outlines tasks, timelines, dependencies, resources, and milestones. This plan serves as a roadmap to guide the project from start to finish. The entire project was planned in such a way that even if we face any hurdles, we will be able to get back on our feet.

Competent Project Team: Assemble a skilled and motivated project team with the necessary expertise to carry out the tasks required for the project. Team members should have clear roles, responsibilities, and a shared understanding of the project’s goals. The team chosen for the project was a great decision to complete the project successfully.

Effective Leadership and Management: A capable project manager should lead the team, ensuring that tasks are delegated, progress is monitored, and issues are addressed promptly. Strong leadership helps keep the project on track. In our project, a critical role of a responsible leader/Team Lead was played hence results are achieved.

Stakeholder Involvement and Communication: Maintain open and consistent communication to manage expectations, address concerns, and ensure everyone is informed about the project’s progress. In our project, we identified and engaged all the key players from the very beginning of the project to make sure we catch the same frequency.

Quality Control: Beginning with the first stage of the project, communication with the QA/QC team should be established. Additionally, we must complete their output reports in the project’s first stage. To make sure that the project is being completed with quality, we need to give the QA/QC department team more consideration during the project execution phase in the oil and gas industry.

Adaptability and Flexibility: Projects can encounter unexpected challenges or changes. Being adaptable and open to adjusting the project plan, scope, or approach as needed is crucial for success. In our project, a plan to welcome uncertain challenges and rectify the run time challenges was intact from the initial stage of the project.

Monitoring and Reporting: Regularly track project progress against the plan, provide status reports to stakeholders and address any deviations from the original plan. In our project, a strong monitoring system was planned to detect a wrong move while doing the job.

Documentation: Maintain thorough documentation throughout the project, including requirements, design documents, meeting minutes, and any changes made. The intriguing portion that is crucial to any project is the one dealing with document control. Every day, we must manage and keep an eye on all document transmissions. Drawings, job cards, and other documents, such as reports, must be transmitted via document transmittal.

Closure and Evaluation: Properly close the project by delivering the final product, conducting post-project reviews, and analyzing the project’s performance. This evaluation provides insights for continuous improvement in future projects. We checked and evaluated our results before bringing the client into awareness.

Client Satisfaction: Ultimately, the success of a project is often measured by the satisfaction of the customer or end-users. Meeting their needs and expectations is a key factor in determining project success. And we got appreciation from the client for our job. We made sure that we don’t miss out on the essential reports which needed to be submitted to the client.

- Project completion report

- Progress report

- Test reportForecast report etc.