Construction Management

PARASCADD is a pioneer in providing unique IT solutions for EPC companies and all the disciplines and departments.

PARASCADD also provides a skilled manpower in various segments of the project like;

- Material Management, Material Planning & Scheduling,

- Inventory Management and Tracking,

- Fabrication Control and Monitoring

- Erection Monitoring,

- Test Pack and Work Packages Monitoring

- On-Job Implementation Services

- Piping Test Pack – Line Walkthrough Services

On-Job Implementation Services includes

Performing Look Ahead Planning analysis for forecasting resource requirement and to mobilise resources in time based on Engineering Schedule & Material ETA dates & Matching Front Analysis

Fabrication tracking & control at Pipe Fabrication Shops including Shop Job Card Creation, Shop Spool Material Issuance, Spool Front Release, Production Fit-up, Production Welding, Non Destructive Testing and Spool Clearance, Spool Painting, Spool Dispatch Clearance, Spool Issue Voucher Request, Shop Change Request (SCR) and Approval for Modifications

Erection tracking & control at erection sites including Spool Receiving at Site, Site Job Card Creation, Erection Component Material Issuance, Erection Planning, Erection Fit-up, Erection Welding, Non Destructive Testing and Spool Clearance, Spool Erection, Erection Item Installation, Flange Joint Clearance, Punch Points, ISO Erection Clearance, Test Pack Construction Clearance, Field Change Request (FCR) and Approval for Modifications.

Piping Test Pack – Line Walkthrough Services

Experienced Site Engineers are deployed for the Piping Test Pack Line Walkthrough in the projects involving the following activities

- Performing Line Walk through before Mechanical Completion

- Verifying the ISO Drawing Revision with respect to Test Package Limits

- Verifying the joint summary with respect to test pack limits

- As per site modification progress update in ISO drawing (supports \ modify joints)

- Preparing as Built Drawings for further mechanical clearance process

- Verifying ISO Revision status before MC

- Reviewing test pack data before MC clearance

- Checking joints/welds physically on-site location

- Hand Sketch Drawing Preparation as per site progress

- Preparing Joint summary list as per site progress

Project: DEEPAK PHENOLICS PROJECT, CUMENE PROJECT

Owner: DEEPAK NITRITE

PMC: THYSSENKRUPP

Engg. Contractor: THYSSENKRUPP Construction

Contractor: ONSHORE INFRASTRUCTURE LIMITED

Project Location: Dahej, Gujarat.

Scope: 3,00,000 ID (approx.)

EPCPROMAN software and Spool Tracking system was used in these projects for Spooling & Spool/Erection Isometrics Drawing generation, Matching Front analysis, Material Control, Fabrication, NDT, Erection, Loop testing & project completion. DEEPAK PHENOLICS project was completed and CUMENE PROJECT is in the advance stage of completion. Spool Tracking System module of EPCPROMAN is used for tracking the Spools to monitor Laydown storage grid location & Dispatch status. Project progress monitoring & reporting was done using the software package. AUTOSPOOL, SPOOLMAN, ERMAN, SPOOL TRACKING, STOREMAN modules were utilized in these project successfully.

Project: G3AU (GADETAN 3 AMMONIA UREA)

Owner: CHAMBAL FERTILIZERS

PMC: TOYO

Engg. Contractor: TOYO

Construction

Contractor:ONSHORE INFRASTRUCTURE LIMITED

Project Location: kota, Rajasthan

Scope: 5,00,000 ID (approx.)

EPCPROMAN software and Spool Tracking system was used in these project for Spooling & Spool/Erection Isometrics Drawing generation, Matching Front analysis, Material Control,Fabrication, NDT, Erection, Loop testing & project completion.G3AU PROJECT is ongoing & 25% Fabrication & 5% Erection is completed. Spool Tracking System module of EPCPROMAN is used for tracking the Spools to monitor Laydown storage grid location & Dispatch status. Project progress monitoring & reporting was done using the software package. AUTOSPOOL, SPOOLMAN, ERMAN, SPOOL TRACKING, STOREMAN modules are utilized in these project successfully.

Projects Executed

| SL No. | Organization | Project | Owner/Client | Discipline | Total Scope (No. of Isometrics) | Status |

|---|---|---|---|---|---|---|

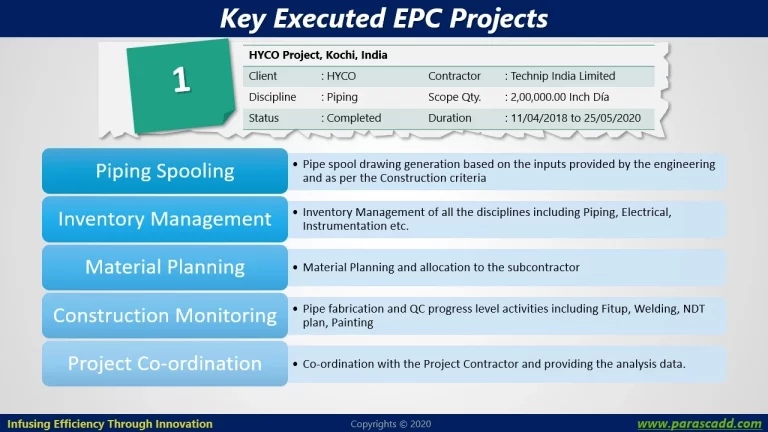

| 1 | HYCO | HYCO Project, Kochi, India | Technip India Limited | Piping | 2,00,000 | Completed |

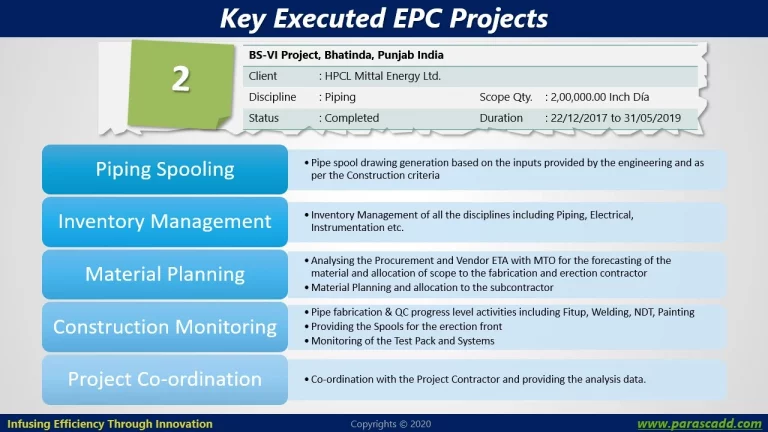

| 2 | HPCL Mittal Energy Ltd. | BS-VI Project, Bhatinda, Punjab India | HPCL Mittal Energy Ltd. | Piping | 2,00,000 | Completed |

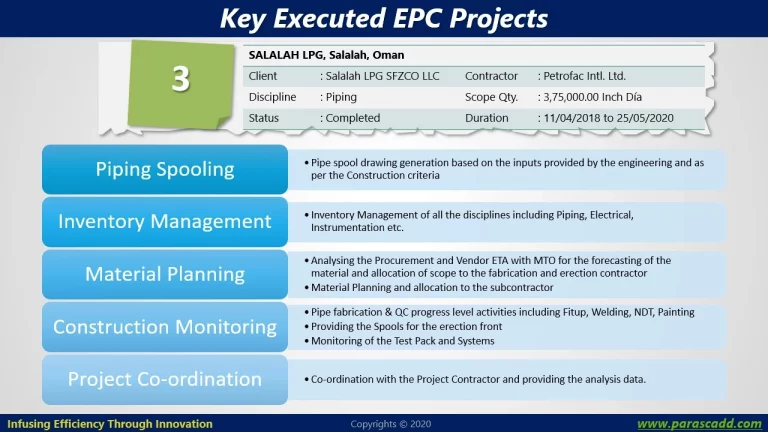

| 3 | Salalah LPG SFZCO LLC | SALALAH LPG, Salalah, Oman | Petrofac Intl. Ltd. | Piping | 3,75,000 | Completed |

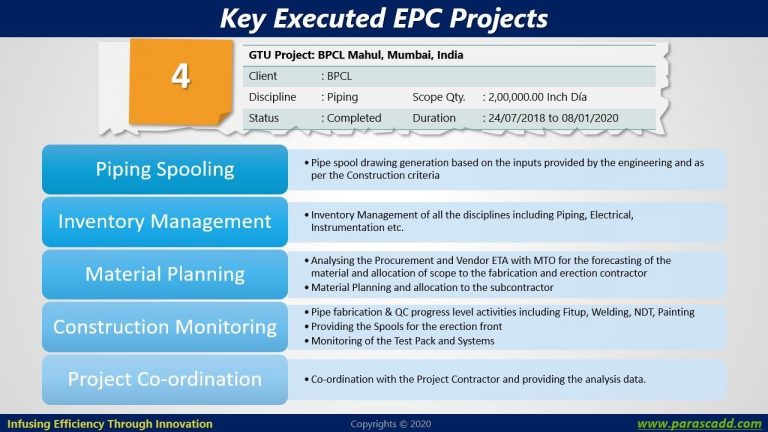

| 4 | BPCL | GTU Project: BPCL Mahul, Mumbai, India | BPCL | Piping | 2,00,000 | Completed |

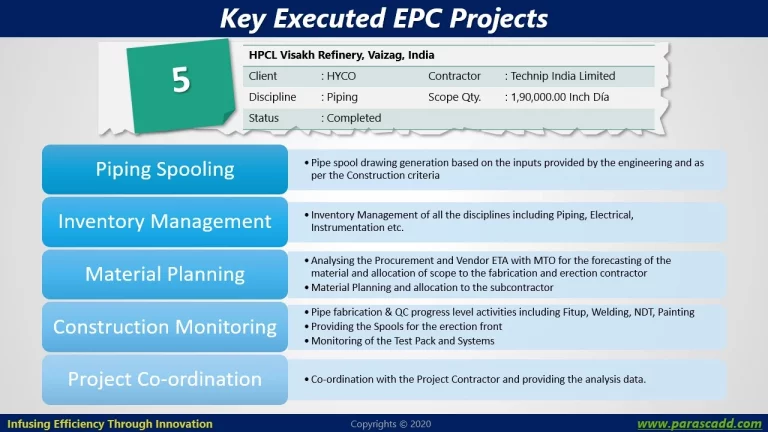

| 5 | HYCO | HPCL Visakh Refinery, Vaizag, India | Technip India Limited | Piping | 1,90,000 | Completed |

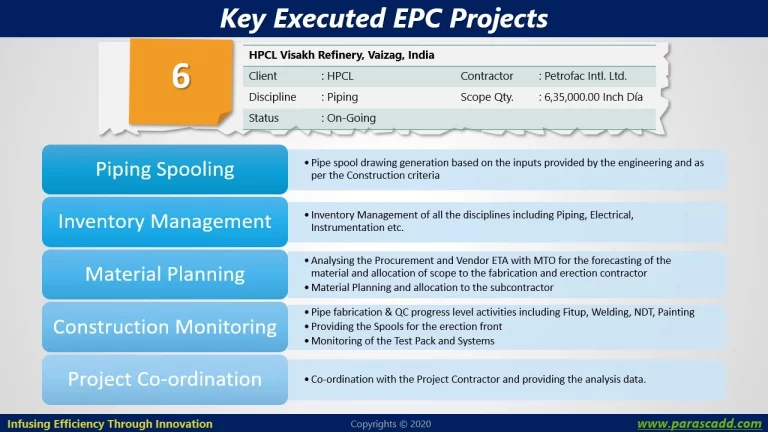

| 6 | HPCL | HPCL Visakh Refinery, Vaizag, India | Petrofac Intl. Ltd. | Piping | 6,35,000 | Completed |

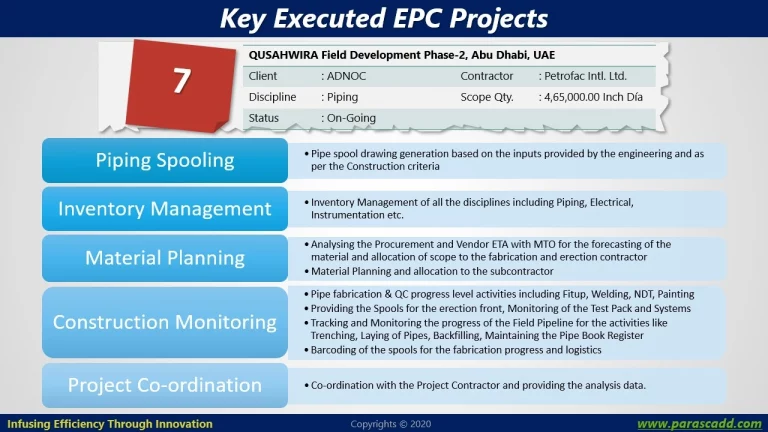

| 7 | ADNOC | QUSAHWIRA Field Development Phase-2, Abu Dhabi, UAE | Petrofac Intl. Ltd. | Piping | 4,65,000 | Completed |

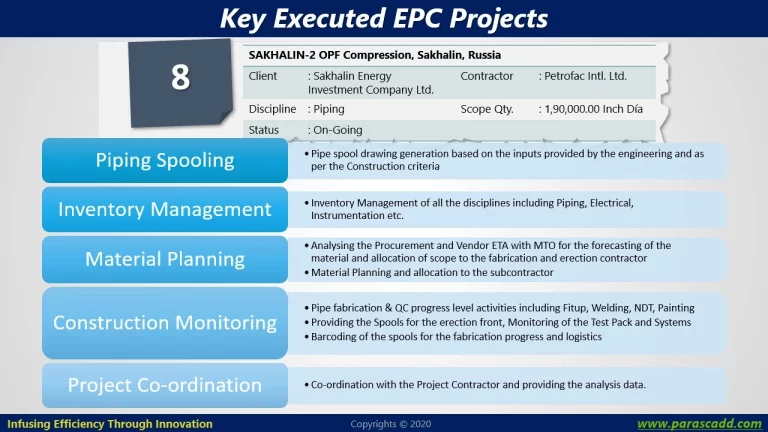

| 8 | Sakhalin Energy Investment Company Ltd. | SAKHALIN-2 OPF Compression, Sakhalin, Russia | Petrofac Intl. Ltd. | Piping | 1,90,000 | Completed |

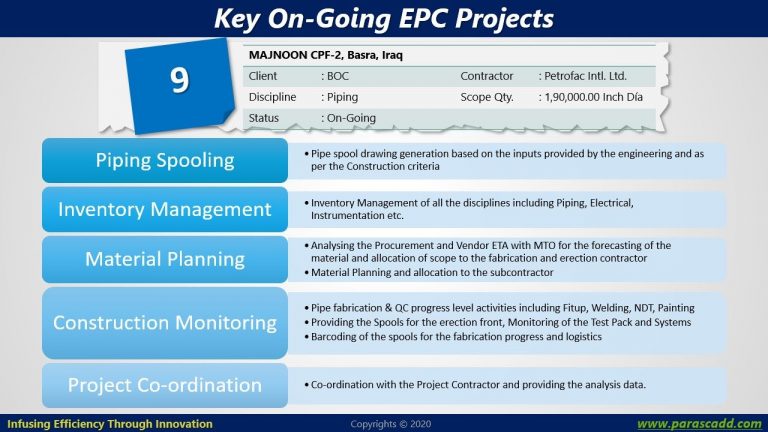

| 9 | BOC | MAJNOON CPF-2, Basra, Iraq | Petrofac Intl. Ltd. | Piping | 1,90,000 | Completed |

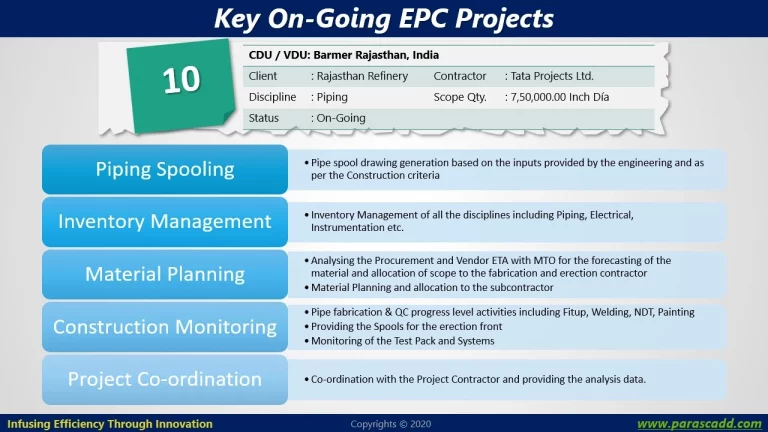

| 10 | Rajasthan Refinery | CDU / VDU: Barmer Rajasthan, India | Tata Projects Ltd. | Piping | 7,50,000 | On-Going |

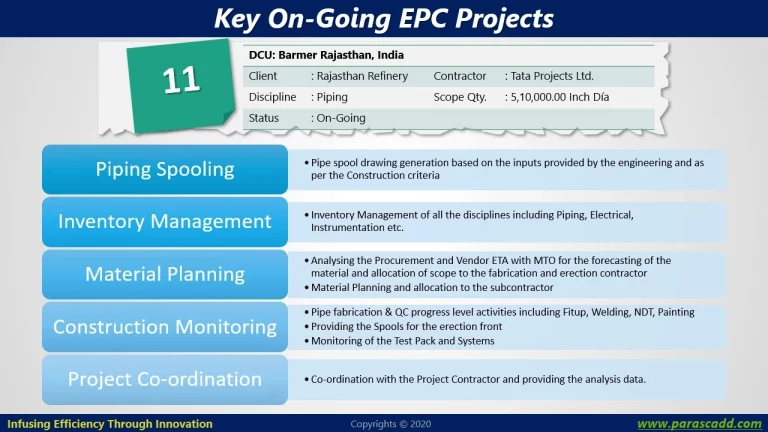

| 11 | Rajasthan Refinery | DCU: Barmer Rajasthan, India | Tata Projects Ltd. | Piping | 5,10,000 | On-Going |

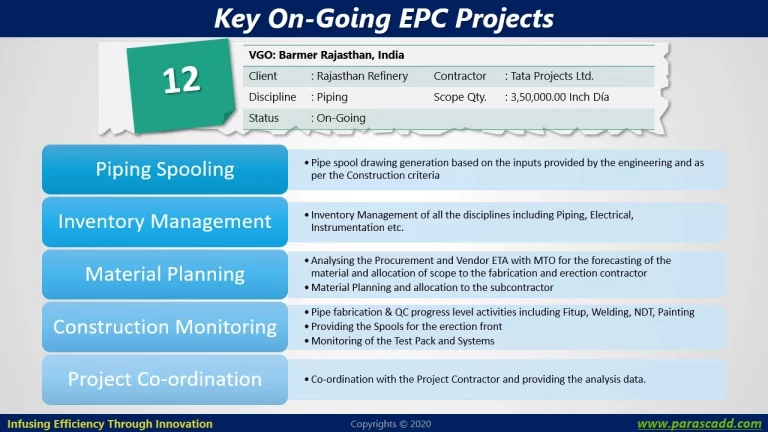

| 12 | Rajasthan Refinery | VGO: Barmer Rajasthan, India | Tata Projects Ltd. | Piping | 3,50,000 | On-Going |

| 13 | Indian Oil Corporation Limited (IOCL) | Vacuum Gas Oil Hydro Treater Unit (VGO HDT) P-25 Expansion, Panipat, Haryana. | Toyo Engineering India Private Limited. | Piping | 3,31,868 | On-Going |

| 14 | HPCL RAJASTHAN REFINERY LIMITED (HRRL) | VGO – VACUUM GAS OIL, PROJECT NO. 500052 | TATA PROJECTS LIMITED. | Piping | 3,77,917 | Final Stage of Completion |

| 15 | HPCL RAJASTHAN REFINERY LIMITED (HRRL) | DCU – DELAYED COKER UNIT 500053 | TATA PROJECTS LIMITED. | Piping | 6,12,080 | Final Stage of Completion |

| 16 | HPCL RAJASTHAN REFINERY LIMITED (HRRL) | CDU VDU (CRUDE DISTILLATION UNIT & VACUUM DISTILLATION UNIT) 500051 | TATA PROJECTS LIMITED. | Piping | 6,93,261 | Final Stage of Completion |

| 17 | INDIAN OIL CORPORATION LIMITED | MS BLOCK | TATA PROJECTS LIMITED. | Piping | 3,12,089 | On-Going |